産業機器ソリューション導入事例

Cold-Chain Transport Equipment Using TIVIP

Vacuum Insulated Reefer Container / Vacuum Insulated Sleeve Box / Vacuum Insulated Roll Box

Now being used for cold-chain transport to various pavilions and restaurants within the Osaka-Kansai Expo venue.

This solution helps reduce electrical energy consumption and contributes to lower CO2 emissions.

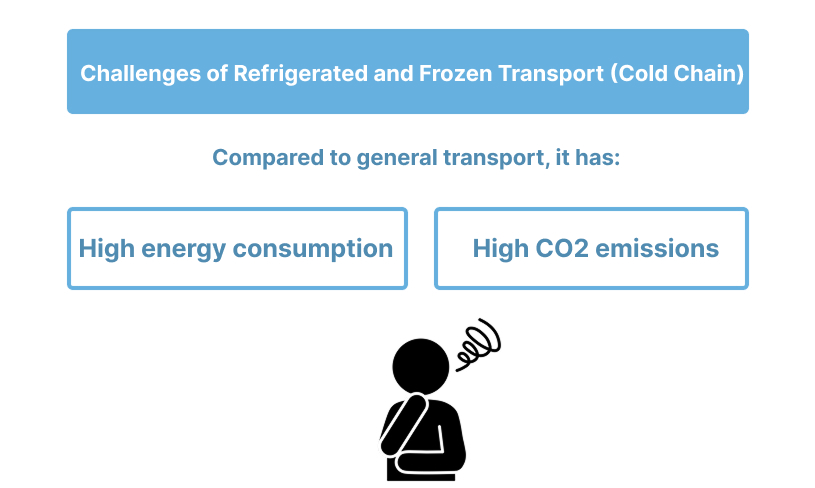

Development Background – Challenges in Refrigerated and Frozen Transport

In recent years, the demand for refrigerated and frozen transport has been growing rapidly.

This is due to a variety of factors, including the increased consumption of frozen and chilled foods resulting from lifestyle changes, the growth of the e-commerce market and home delivery services, and the rising circulation of goods like pharmaceuticals and vaccines that require strict temperature control. This has led to a greater reliance on transport methods that can maintain low temperatures.

However, refrigerated and frozen transport consumes more energy and produces more CO2 than general transport.

Emissions from the cooling units and idling of refrigerated trucks are a particular concern, making CO2 reduction an essential part of global warming countermeasures.

Therefore, as the demand for cold-chain transport expands, there’s a growing need for sustainable initiatives, such as adopting low-environmental-impact

transport technology, utilizing renewable energy, and designing more efficient logistics systems.

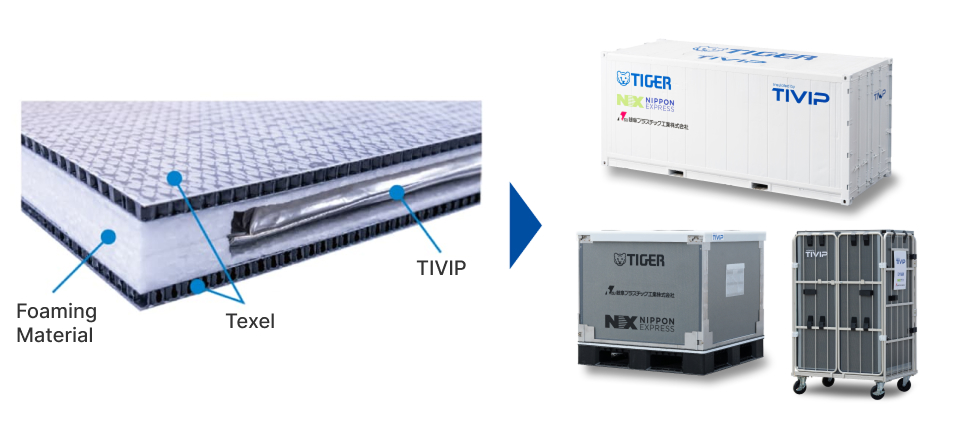

Solution to the Challenges

Our company newly developed TIVIP, a thin, Stainless Steel Vacuum Insulation Panel with excellent thermal performance. By combining it with

Gifu Plastic Industry’s lightweight and high-strength resin honeycomb panels, Texcel, we have created a lightweight and robust insulated unit panel.

By adopting this insulated unit panel in Nippon Express’s Protect BOX transport sleeve box to create the “”Protect BOX Thermal,”” it became possible to maintain a stable temperature for long periods during transport. This also reduces the need for conventional coolants or heating materials.

By significantly suppressing electricity consumption, this solution contributes to lowering CO2 emissions in refrigerated and frozen transport.

Insulation Unit Panel Installed on Transport Equipment

Operational Results at the Expo and Future Development Plan

Starting May 27, 2025, cold-chain transport equipment with temperature-maintaining capabilities began to be used at the Osaka-Kansai Expo.

It’s used for transporting temperature-sensitive goods like food, drinks, and souvenirs to pavilions and restaurants within the venue.

During transport, temperature data is being collected and managed to support future product commercialization and analysis.

Looking toward a commercial release in fiscal year 2026, the Protect BOX Thermal is being considered for use in a wide range of fields, including food,

pharmaceuticals, electronic components, and art. The goal is to address challenges like temperature rise in summer and freezing in winter.

Example of a Demonstration at the Expo (Usage started on May 27, 2025)

For On-site/Off-site Transport

Used for cold-chain transport of goods to various pavilions and restaurants within the Expo venue.

Vacuum-Insulated Sleeve Box

“Protect BOX Thermal”

Vacuum Insulated Roll BOX

In addition, there are plans to conduct a comparative study on power consumption and CO2 emissions for a future vacuum-insulated reefer container (refrigerated and frozen) that will have an additional layer of TIVIP (vacuum insulation material). This study will visually demonstrate the benefits of the additional insulation, such as improved energy efficiency and reduced environmental impact, using clear numerical data.

▼ Vacuum-Insulated Reefer Container Being Considered for Future Implementation

Outdoor Installation (for storage)

About Collaborative Partners in the Expo Demonstration

Nippon Express is the core company of the NX Group, providing high-quality and sustainable logistics services globally by utilizing air, marine, rail, truck, warehousing, and IT. It is also the “Recommended Logistics Partner” and “Designated On-site Cargo Handling Operator” for the Osaka-Kansai Expo.

We manufacture and sell plastic industrial materials, industrial and medical parts, daily use goods, water pipe fittings, and TECCELL, a lightweight, high-rigidity honeycomb sandwich panel. TECCELL is used to explore infinite possibilities in the logistics field.

To Be Exhibited at the “Future Society Showcase Project” “Future Life Experience”

The “Stainless Steel Vacuum Insulation Panel Technology” has been developed and demonstrated with support from Osaka Prefecture’s “Carbon Neutral Technology Development and Demonstration Project,” which backs companies that are challenging the development and demonstration of cutting-edge technologies that contribute to carbon neutrality.

A portion of this technology will be exhibited from October 7 to October 13, 2025, at the “Future Life Village” within the 2025 Japan World Exposition’s “Future Society Showcase Project” “Future Life Experience.”

・Date: Tuesday, October 7, to Monday, October 13, 2025

・Location: Inside the Expo venue (near the West Entrance Plaza), Future Life Village, Future Life Experience

・ Exhibit Content: Tiger Corporation’s Stainless Steel Sealed Long-Life and Non-Combustible Vacuum Insulation Panel Technology Development

and Demonstration

・This will be a joint booth with other companies from the “Carbon Neutral Technology Development and Demonstration Project.

Related Links

About Vacuum Insulation Technology>

What is “Vacuum Insulation Technology,” a core competence of Tiger Corporation?

Stainless Steel Vacuum Insulation Panel TIVIP>

Learn about the mechanism and features of Tiger’s Stainless Steel Vacuum Insulation Panel. With its high thermal insulation, long lifespan, and non-flammability, it is expected to play a major role in the transportation and building materials industries

Other Case Studies

Catalog

About Industrial Equipment Solutions

Contact Us

For more information, contact us from here;

On research and development, methods of applying vacuum insulation technology,

and inquiries about partnership