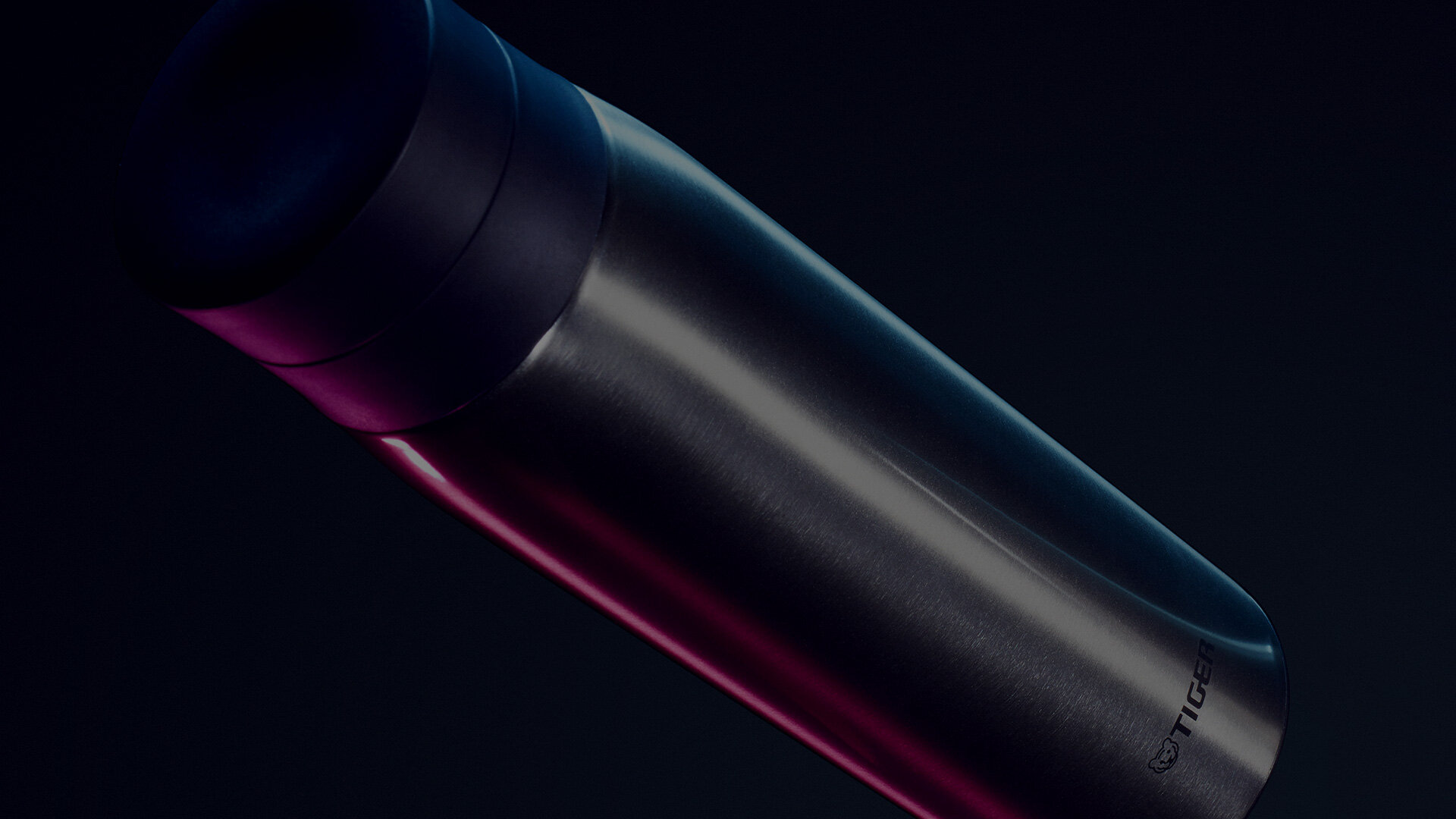

TECHNOLOGY

Vacuum Insulation Technology and

Heat

Control Technology.

The Dual Axes of Tiger Corporation’s

Heat Technology.

Vacuum Insulation Technology

Evolves for the Future

It All Started with Unbreakability

Tiger Corporation first developed a vacuum bottle in 1923. We used zinc plate for the bottle’s case, instead of the tinplate that was commonly used at the time, and packed cardboard between the case and the inner bottle as a buffer material to increase strength. The Great Kanto Earthquake struck in the same year, and while many vacuum bottles from other companies broke, all of the 100 vacuum bottles that had been delivered by Tiger remained unbroken, leading the company’s reputation for performance to soar.

Vacuum Bottle Presented to Showa Emperor

In 1954, Tiger Corporation had the honor of presenting one of its products to the then Emperor of Japan (Showa Emperor). In this same year, the Emperor had been extremely interested in a glass lined jar when seeing it for the first time during a visit to Hokkaido, prompting the Imperial Household Agency to make a request to Tiger Corporation. Our offering was a commercial wide opening glass lined jar, specially manufactured with chrome plated brass. Also, in May 1964, we had the honor of presenting two portable vacuum bottles to the then Crown Prince, who went on to become the Heisei Emperor.

Handy pot adopted by Orient Express

Around 1980, Tiger’s Handy Pot (Dimple Pot) was used as passenger equipment on the Orient Express, a long-distance overnight train traveling through Europe. It was the only Japanese product to be used for this purpose, as it was highly evaluated for its high heat-retaining performance and safety features that prevent breakage.

Official Supplier to the Olympic Games

The 14th Winter Olympic Games were held in Sarajevo, Yugoslavia, in February 1984. Two years earlier, in 1982, Tiger Corporation was chosen as an official supplier because its products offered high heat retention, resistance to breaking when dropped, and convenience for portable use – especially in outdoor activities and sports. At the Games, the products were used not only by athletes, but also by officials and the media. This was the first time in the history of the Olympics that a Japanese vacuum bottle had been chosen as an official supplier product.

Vacuum Bottles Evolved to Become Stainless

In 1983, when the first Japanese people summitted Mt. Everest without the use of oxygen, they carried with them Tiger Corporation double stainless steel bottles, food warmers, cassette grills, and pressure cookers. A member of the team who participated in the successful ascent reported that, “More than anything, we were able to trust that the double stainless steel bottles would not break, in contrast to conventional bottles. And the higher up you climb and the harsher the conditions become, the more difficult the human body finds it not only to process solid food, but also liquids. In these circumstances we needed green tea and hot water, so the double stainless steel bottles were priceless. Being able to drink warm drinks even at an altitude above 8,000 meters was a first for me”.

Heat Storage System for Engine Warm-up adopts the vacuum insulated tank

The world‘s first Heat Storage System for Engine Warm-up was cooperatively developed with Denso and installed in the hybrid car “Toyota Prius” (2004 model) for the North American market. The furnished vacuum tank stores the water used to cool the engine which is warmed during driving. When the engine is restarted, it efficiently supplies the warmed water to the engine, so that the engine temperature can be quickly raised to the optimum level. As a result, it contributes to the reduction of exhaust gas emissions and the protection of the global environment.

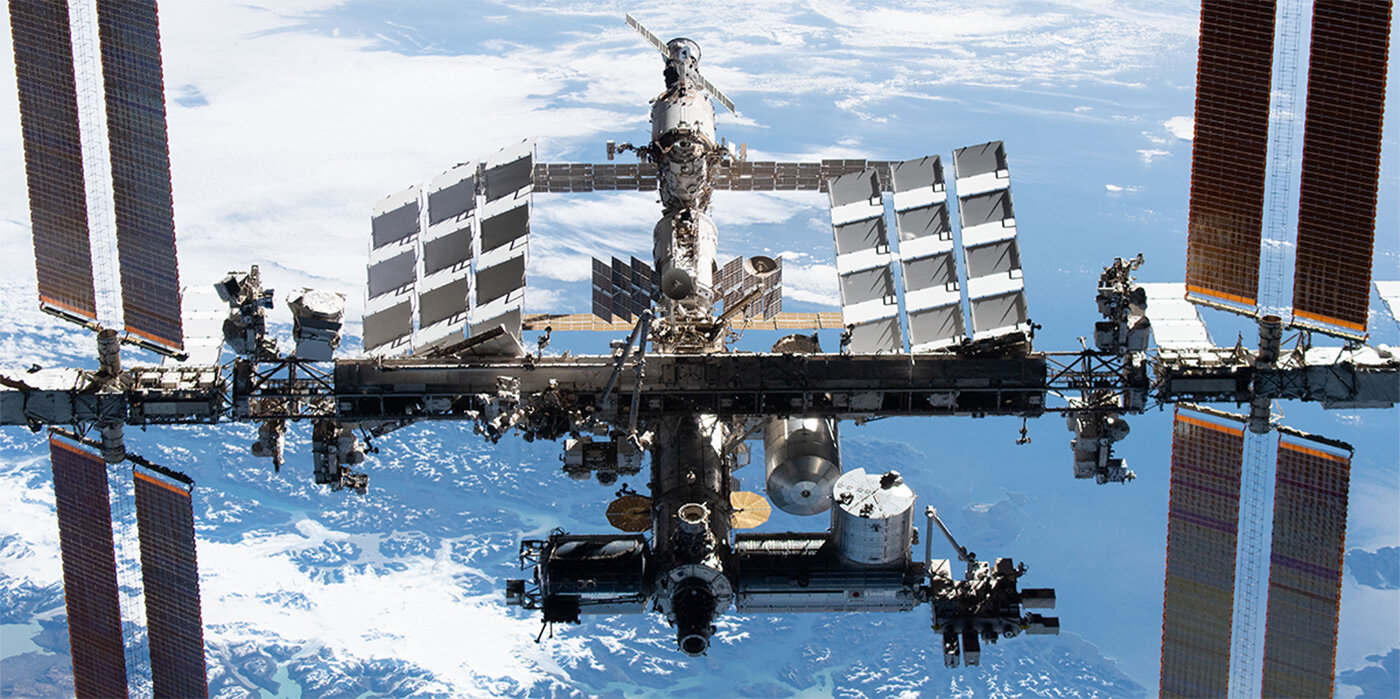

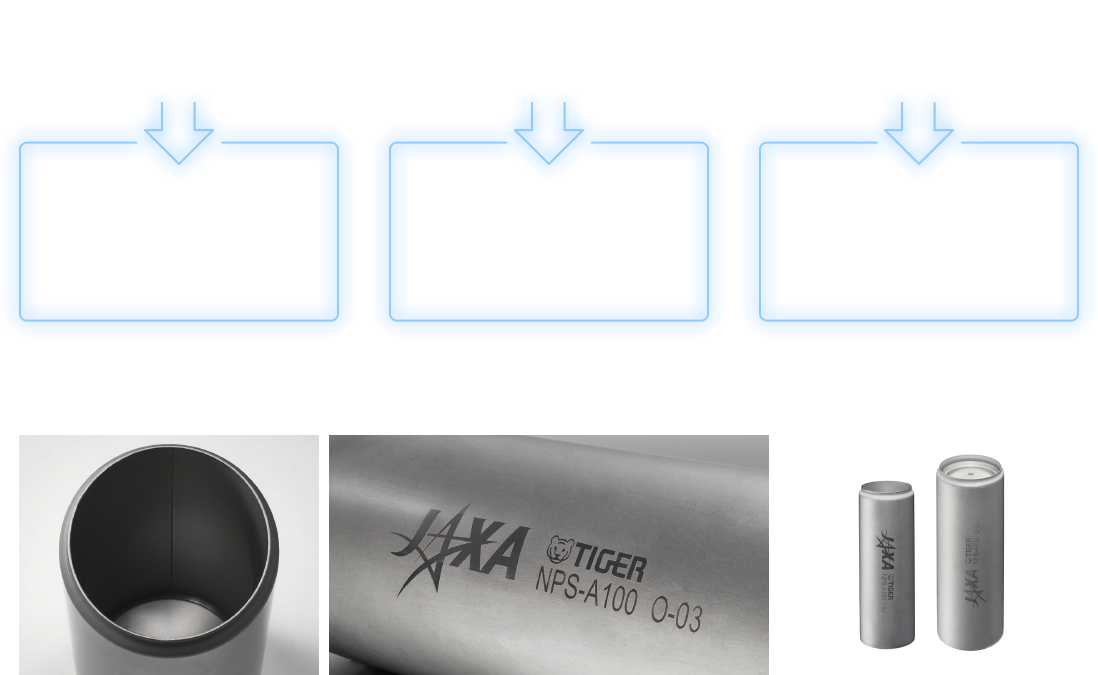

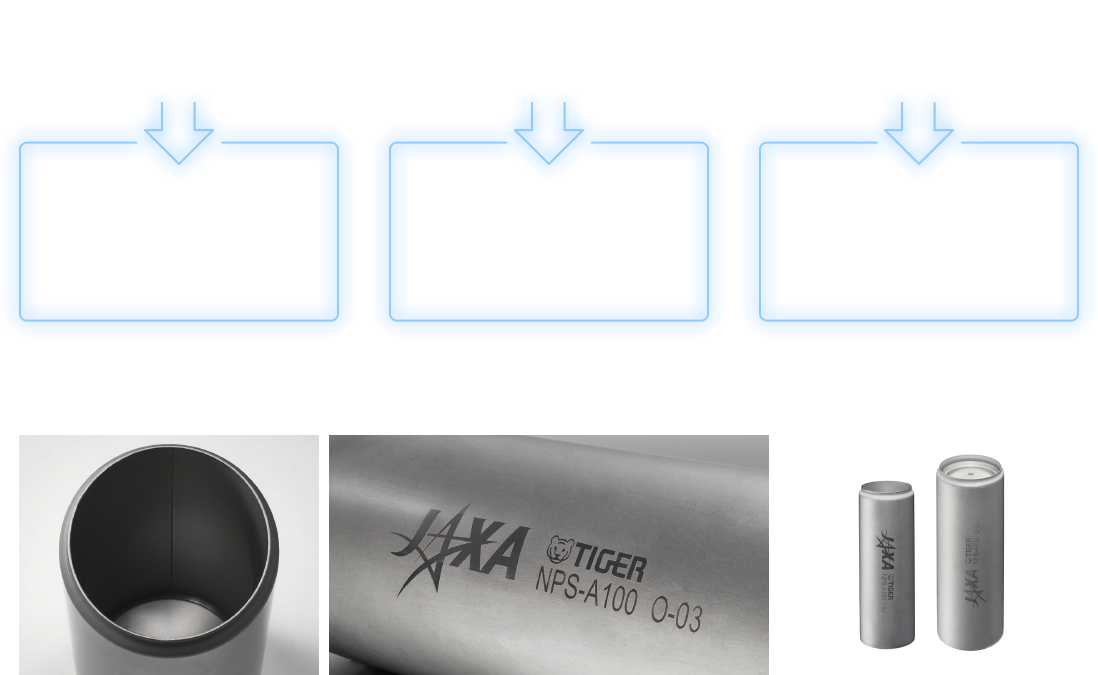

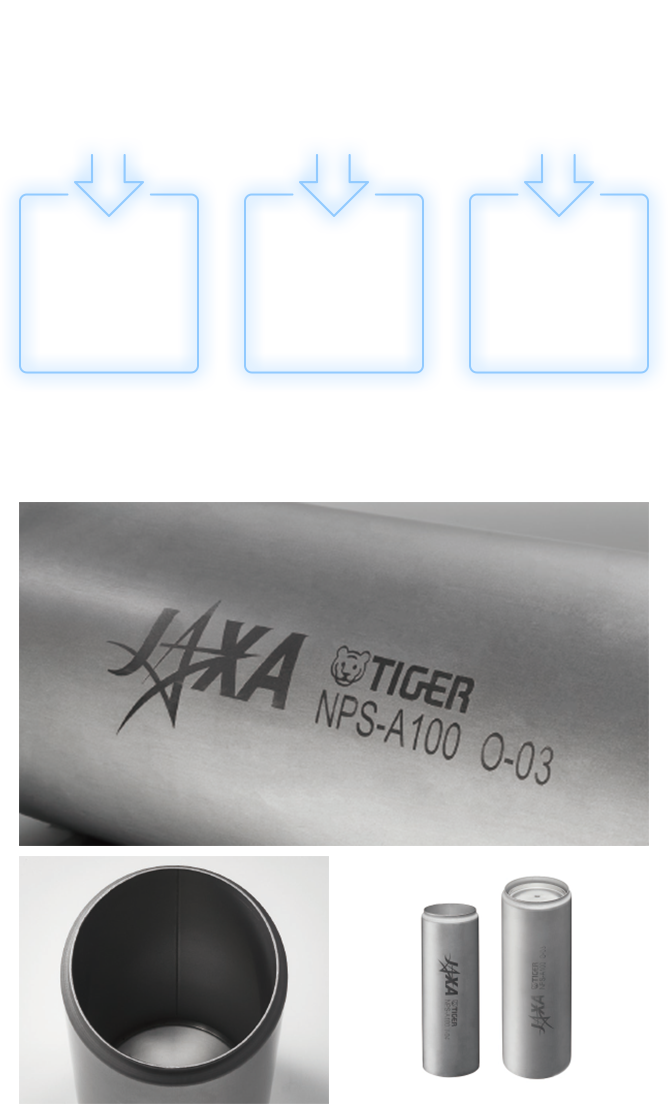

Bringing Samples from Space to Earth

On November 11, 2018, a small re-entry capsule carrying materials from the International Space Station (ISS) returned to Earth. Tiger Corporation was responsible for the development of the double insulated vacuum container in this small re-entry capsule. The company took on the challenge of a mission to keep important samples from experiments in space in a cool state and to withstand the violent impact if dropped in order to successfully bring them to Earth. The samples were loaded into the capsule along with coolant on the ISS, and were kept at a temperature of 4℃ for five days and 15 hours.

(Photo: Provided by JAXA/NASA)

(Photo: Provided by JAXA/NASA)

The 2nd Phase of the Space Challenge

Tiger Corporation product went into space again on June 4, 2021. On this day, a SpaceX Dragon CRS-22 carrying the double vacuum insulated temperature retention transportation container, that Tiger Corporation was involved in the development of, was launched. The mission here was to deliver experiment samples to the Japanese experiment module Kibo on the ISS, and to bring them back to Earth. The ultimate goal of Tiger Corporation’s mission was to meet the three new performance demands of “maintaining temperature for a long period,” “reduced size,” and “reusability”.

(Photo: Provided by JAXA/NASA)

Results Exceeding Requirements

Creating a New Lifestyle

with Heat Control Technology

Stainless Steel Rice Warmer Makes its Debut in Shinkansen Buffets

The Tokaido Shinkansen started operations in October 1964. It was a hot topic along with the Tokyo Olympic Games at the time. 30 Tiger Corporation stainless steel rice warmers were used in the limited express buffet (cafeteria) on the Shinkansen trains. These rice warmers had the ability to keep 160 bowls’ worth of rice warm, and enabled passengers traveling for leisure, business, and other purposes to enjoy hot rice while on the train.

The Birth of Today’s ‘Takitate’ Brand

Takitate’ electric rice warmers were first sold in 1970. Tiger Corporation released its first electric rice cooker the following year, and the ‘Takitate’ brand continues to this day, 50 years after it was launched. The combination of heat control technology and materials used in the inner cooking pot deliver increased performance, and the design fits the lifestyle of the times while delivering abundance to dining.

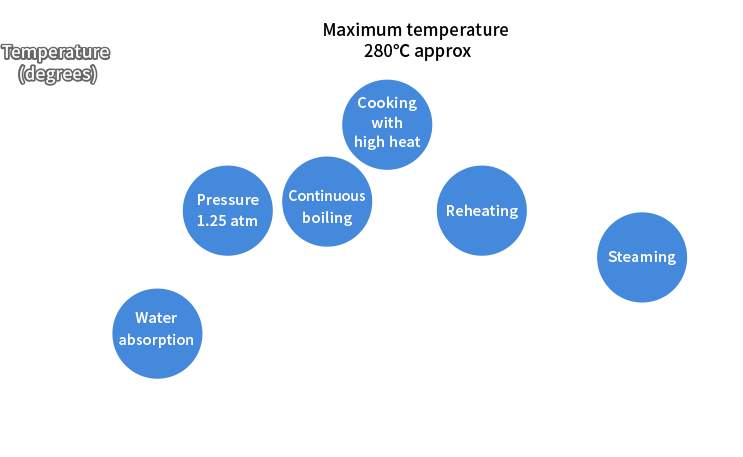

Donabe Gohobi Taki Wins Eight Awards for Home Appliances

The JPL DONABE GOHOBI-DAKI pressure IH jar rice cooker won the Gold Award in the rice cooker category of the “Home Appliance Awards 2020-2021,” as well as the Best Buy of the Year 2021 in “Home Appliance Critic” and Best Buy of the Year 2021 in “MONOQLO,” among others. The ‘Donabe Gohobi Taki’ cooks rice thoroughly with high heat of up to 280℃, which only earthenware pots are capable of, and radiant heat from the far infrared effect of the earthenware pot, while the fine bubbles from the earthenware pot envelop the rice. The rice cooked in the ceramic inner pot has a sweetness and bounce that only Tiger’s best products can provide,” and “The tastiness of the rice is so good that my family is impressed.

- ・GetNavi x Kaden Watch ‘2020-2021 Kaden Awards,’ Rice Cooker Category, Gold Prize

- ・Shinyusha ‘Kaden Hihyou,’ 2020 Rice Cooker Category, Best Buy #1

- ・Tokuma Shoten ‘GoodsPress’ GP Award 2020, Home Appliance Category, Everyday Excellence in Dining Award

- ・Kobunsha ‘VERY,’ February 2021 issue, Everyone’s Glad They Bought One Home Appliance Awards, Tabletop Excitement Award

- ・Shinyusha “Home Appliance Critic” Best Buy of the Year 2021

- ・Shinyusha “MONOQLO” Best Buy of the Year 2021

- ・Tokuma Shoten “GoodsPress” 2021 Best Hit of the Year in the rice cooker category

- ・One Publishing “GetNavi” March 2022 issue, Everyone’s Wishlist Ranking: Best Buy in Rice Cooker Category

Technology to Harness Heat

Vacuum Insulation Technology

Put simply, vacuum insulation technology can be described as having a heat resistance that works like magic.

The heat and cold retention technology that came about through the development of glass vacuum bottles has evolved into advanced vacuum insulation technology. In addition to stainless steel vacuum bottles, it is also used in the space industry and other cutting-edge fields of industry.

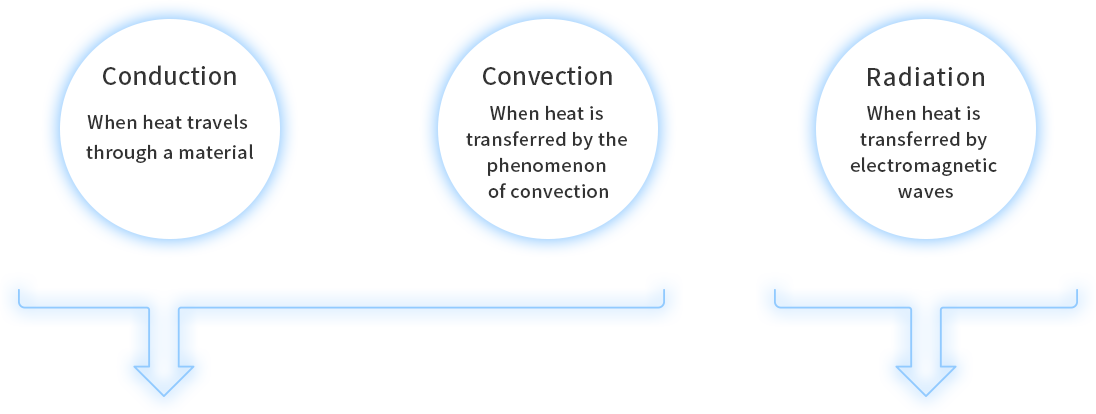

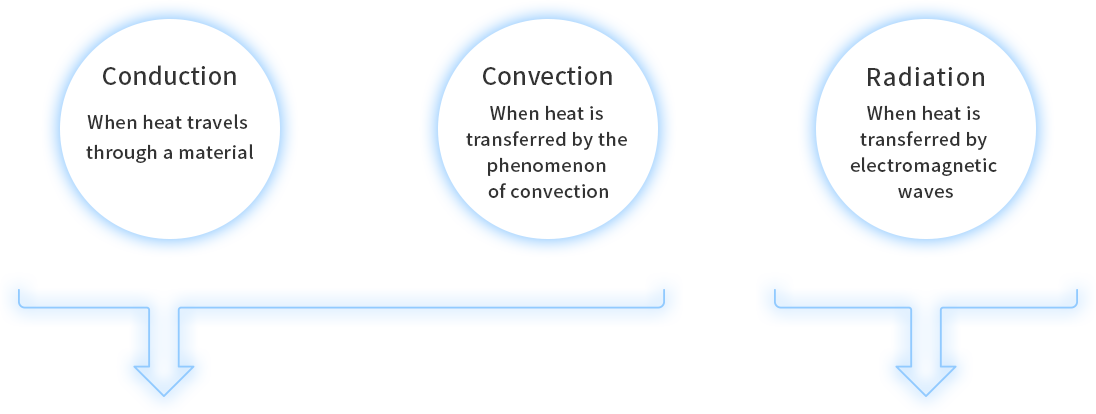

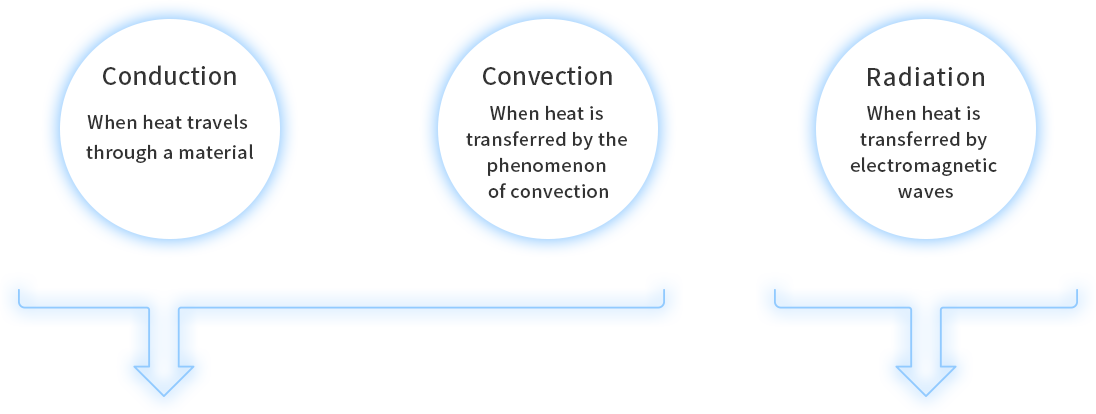

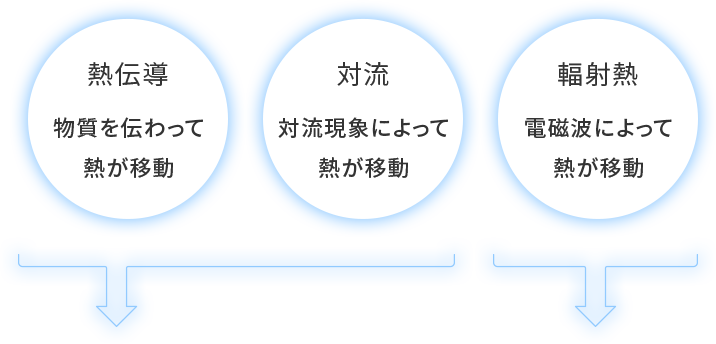

The Three Movements of Heat

How

Insulation

Works

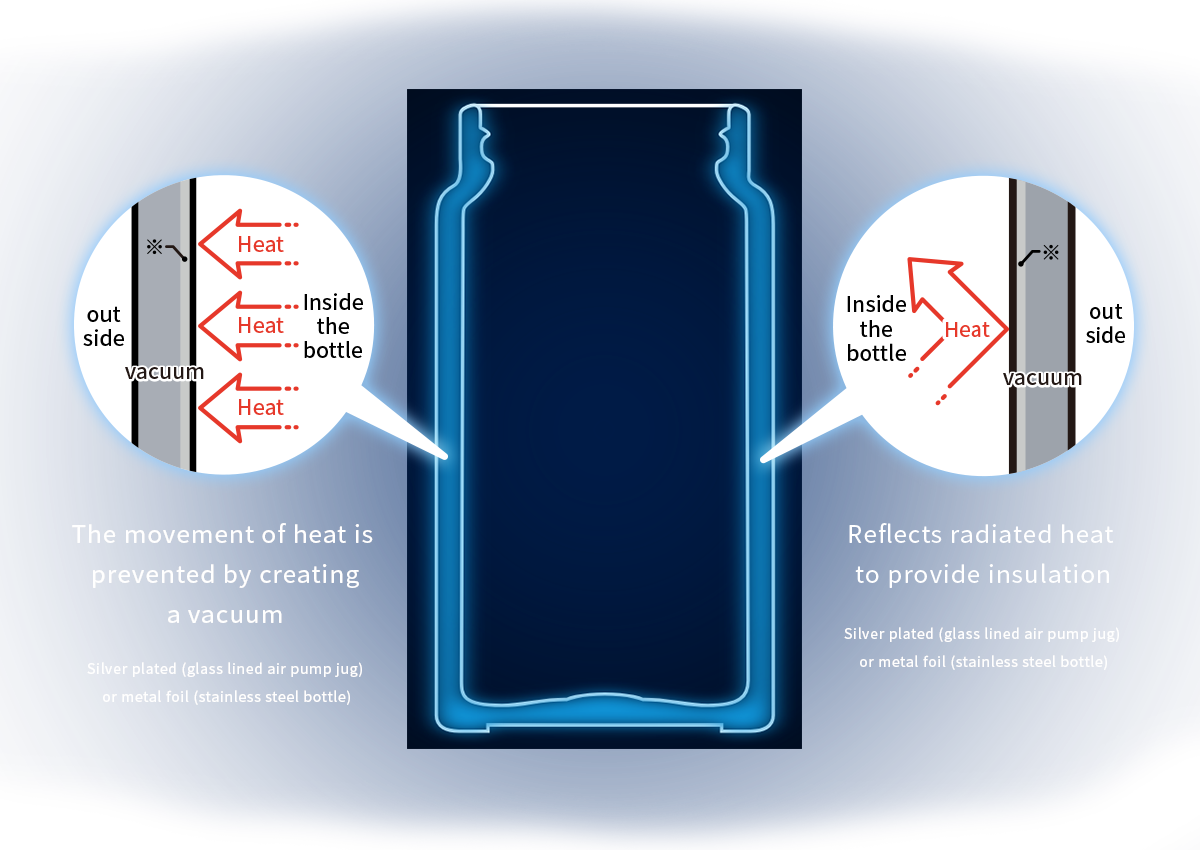

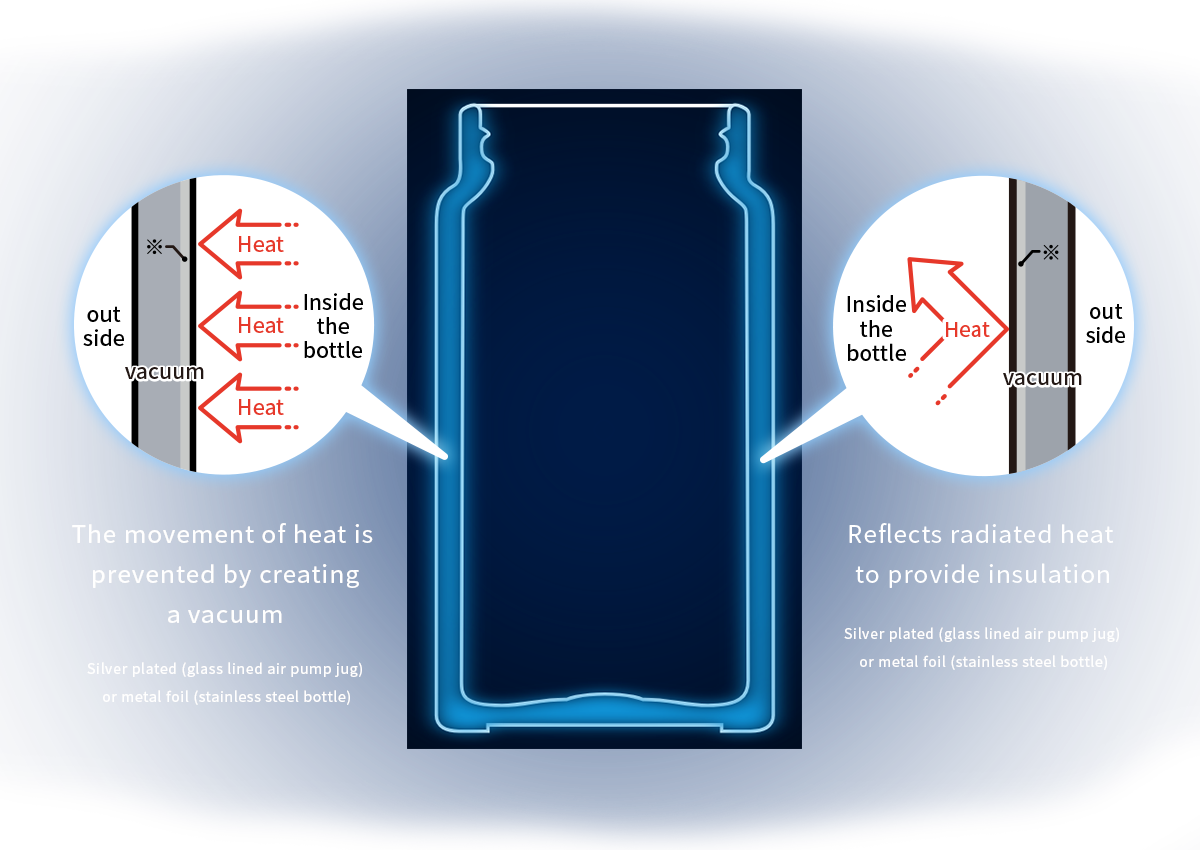

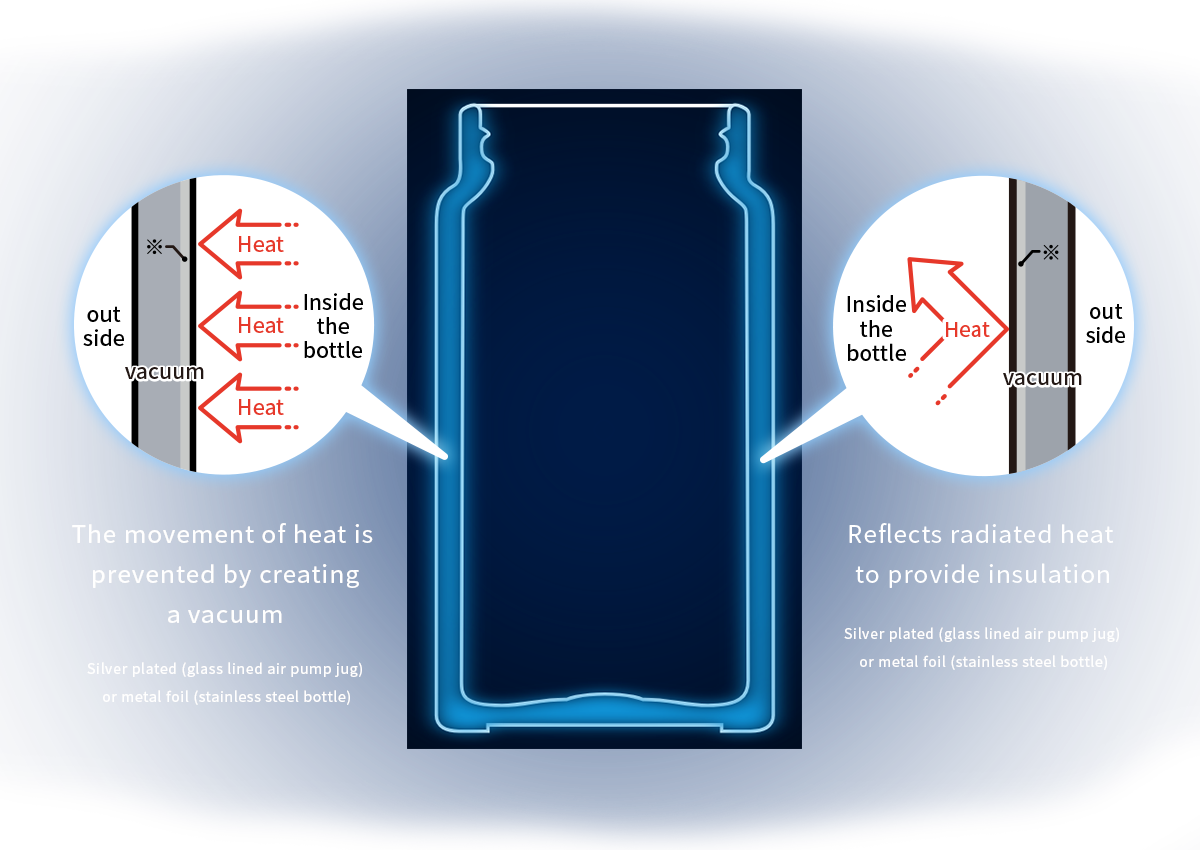

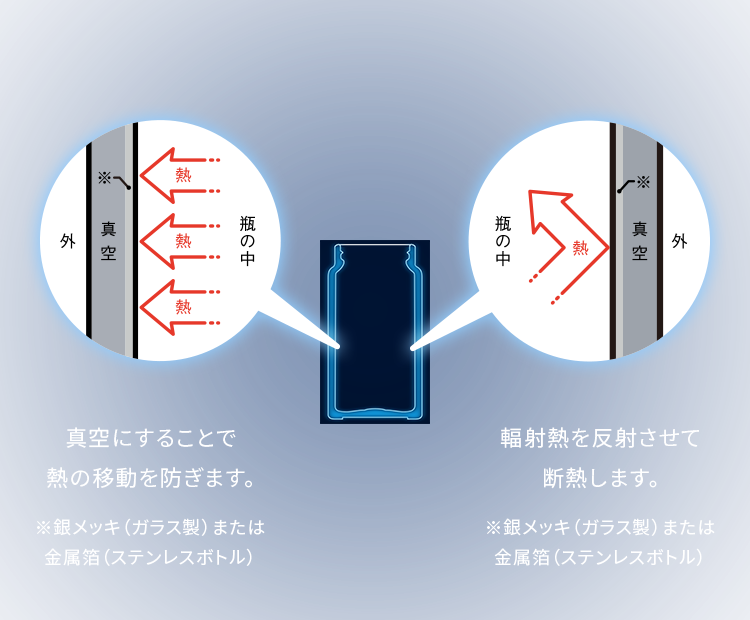

Why does heat not move through a vacuum?

Because there are almost no air molecules to transfer the heat

Heat is transferred through the molecules that make up a material. This is called heat conduction. While a vacuum as defined by Japanese Industrial Standards (JIS) does contain a miniscule amount of molecules, it conducts almost zero heat.

Heat does not move because there is no air present

When a heater is working, warm air rises and cold air sinks. This is because heated air rises upwards and conveys the heat. The phenomenon does not occur in a vacuum, which contains no gas.

But radiated heat moves through a vacuum

So we deal with this problem by reflecting it

In the same way that the heat from the sun reaches the earth, radiation (heat energy) is transmitted even through a vacuum. As such, vacuum bottles have silver plating or metal foil sandwiched between vacuum layers to reflect heat radiation and keep heat inside.

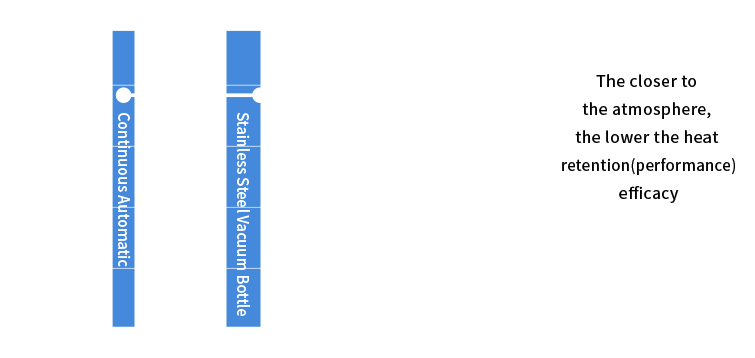

Fully Sealed with Continuous Automatic Vacuum Equipment Achieving a Space-like Vacuum

A large number of vacuum bottles are placed in a high vacuum furnace (continuous vacuum system) at about 500℃ and 10-4Pa where the air is removed to create a vacuum and the exhaust port is fully sealed with melted brazing material. Using the vacuum brazing method achieves a so-called ‘high vacuum (10-3Pa)’, which is equivalent to an altitude of about 90-250 km above the ground, equivalent to the boundary with outer space.

The closer the pressure of a vacuum double layer is to the atmosphere, the less effective the heat retention (performance) becomes. Stainless steel vacuum bottles achieve a ‘high vacuum (10-3Pa)’ that is close to the vacuum of space. With this high degree of vacuum, they achieve excellent heat retention performance

Technology to Manipulate Heat

Heat Control Technology

Delicious food with heat control technology

The technology for heat retention and heating that came about from the development of electric rice cookers has evolved into advanced technology. Heat is controlled by precisely programmed software that combines the heating method and heat-transfer material to plot the optimal heating curve for each type of food.

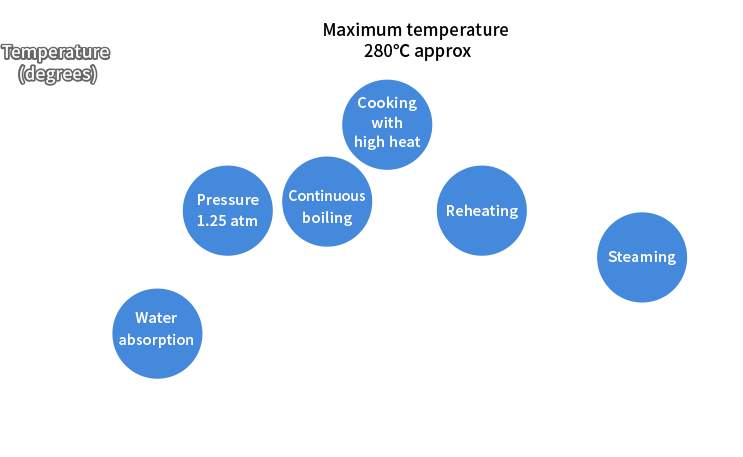

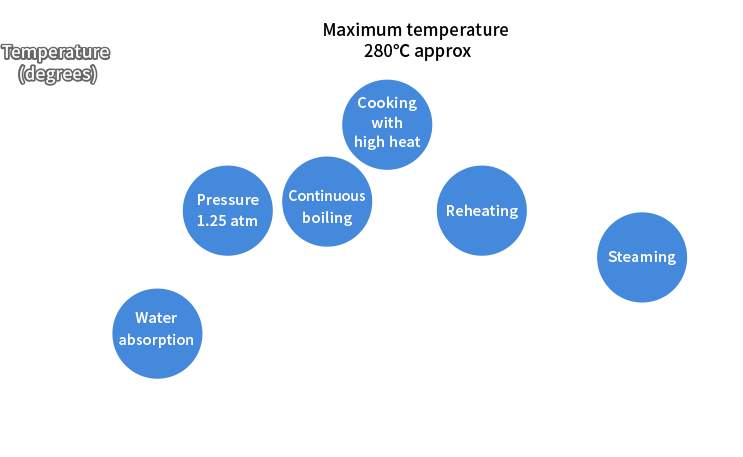

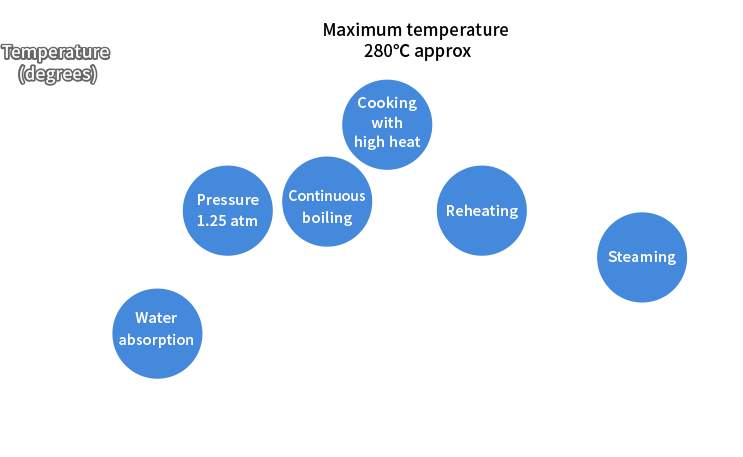

Plotting the Ideal Heating Curve

By experimenting with combinations of inner pot material and white rice, brown rice, and other foods, Tiger Corporation has accumulated a vast amount of data on heat changes. Programming allows for heating to be optimized by food, meaning delicious food can be prepared using the ideal heating curve.

Programs Perfectly Matched to Heating Method and Material

The heating method and the material that carries the heat. These two elements are optimally configured and combined with programs based on heat change data results to ensure delicious food.

Tiger Corporation’s Heat Control Technology Also Used in Industry

ステレスジャー、新幹線の

ビュッフェにデビュー。

Medical Care

Making Possible Medical Transport Requiring Strict Temperature Control

The vacuum bottle structure constant-temperature transport container, which makes the environmental temperature of the inner vacuum bottle for an outer vacuum bottle, opens up new possibilities for medical transport.

今も続く「炊きたて」

ブランド誕生。

Homes

High Heat-insulating Panels for Homes Verified in Harsh Environments

Tiger Corporation is developing vacuum insulation panels which suffer no deterioration in performance even over long periods of time in harsh environments.