Case Studies of Industrial Equipment Solutions

Fusion of Space Technology and Vacuum Insulation Technology:

Business Alliance with a JAXA Venture for the Development of an Ultra-High-Performance Insulated and Refrigerated Container

Tiger Corporation has partnered with TwinCapsula Inc., a JAXA venture, to develop a next-generation insulated and refrigerated container utilizing technology acquired through space development. This project aims to solve temperature control challenges in biomedical logistics.

Background to the development: Terrestrial Application and Social Implementation of Space Technology

In recent years, the application of advanced technologies cultivated through space development to civilian fields has gained attention. In particular, the highly sophisticated thermal control technology developed for the extreme environment of space holds great potential for use in terrestrial applications that require precise and high-performance temperature management.

Tiger Corporation’s Commitment to Technological Innovation

With over 100 years of expertise in vacuum insulation technology, Tiger Corporation is striving for further innovation. We are taking on the challenge of creating new value through collaboration with different industries and fields. By engaging in technology development for the cutting-edge domain of space, we aim to create products that go beyond the limitations of conventional vacuum insulation technology.

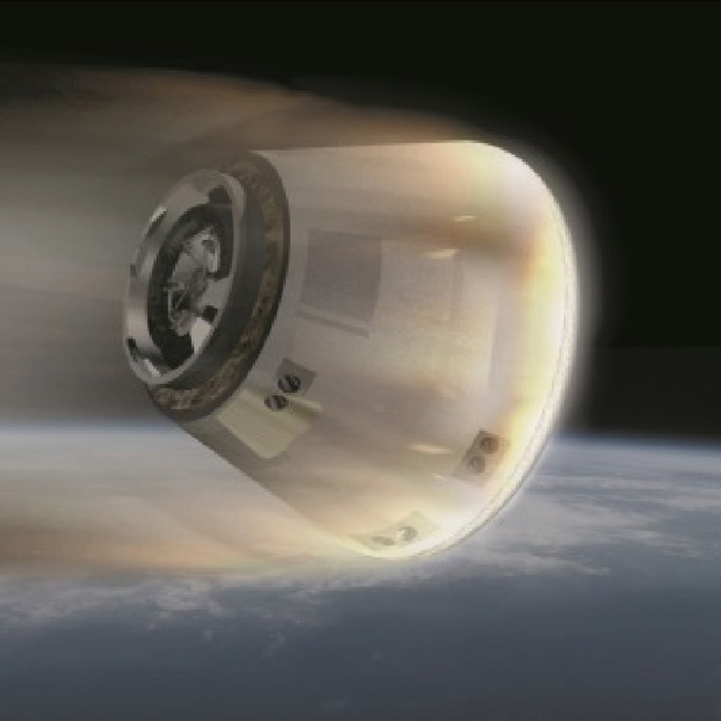

TwinCapsula × Tiger Corporation: Bringing Space Technology to Earth

By combining Tiger Corporation’s long-standing expertise in vacuum insulation with JAXA’s thermal control and design know-how for spacecraft, a groundbreaking mission was accomplished. In November 2018, JAXA became the first in Japan to successfully retrieve space-based experimental samples (such as high-quality protein crystals) from the International Space Station, bringing them back to Earth in a refrigerated state using a unique re-entry capsule. To develop and commercialize the technology from this re-entry capsule for terrestrial use, Kazuhiro Miyazaki and Ryuta Hatanaka, who were key members of the capsule development project and led the insulated container development at JAXA, founded the JAXA venture, TwinCapsula Inc

The Challenges

Traditional refrigerated boxes used for transporting pharmaceuticals and other items face the following challenges.

Risk of Temperature Excursion

In the biomedical field, it is critical to maintain proper temperatures when transporting samples, vaccines, cells, drugs, and biological tissues.

Although various refrigerated containers and transport services are available, temperature excursions during transit occur frequently. This can lead to significant economic losses, such as the disposal of temperature-sensitive goods, making reliable temperature maintenance extremely important.

High Transport Costs

Currently, it is difficult to transport small quantities of items reliably and compactly at a low cost. Traditionally, even for small shipments like a few test samples,

large refrigerated boxes filled with a significant amount of coolants or dry ice were necessary to ensure an adequate preservation period.

This results in high shipping costs, especially for long-distance or international transport.

The Solution: “BAMBOO SHELLter” – An “Ultra” Insulated Container for Biomedical Transport

To solve these challenges, TwinCapsula and Tiger Corporation formed a technological partnership to develop the “”BAMBOO SHELLter,”” an “”ultra”” insulated and refrigerated container. With a slim, bamboo-like shape, this compact and ultra-high-performance container (under 2L in volume, maintaining temperatures of -70°C or lower for over 7 days) provides a new solution. By enabling the secure and compact refrigerated transport of small quantities of samples and cells, it helps address critical issues in the medical field and beyond.

A New Solution

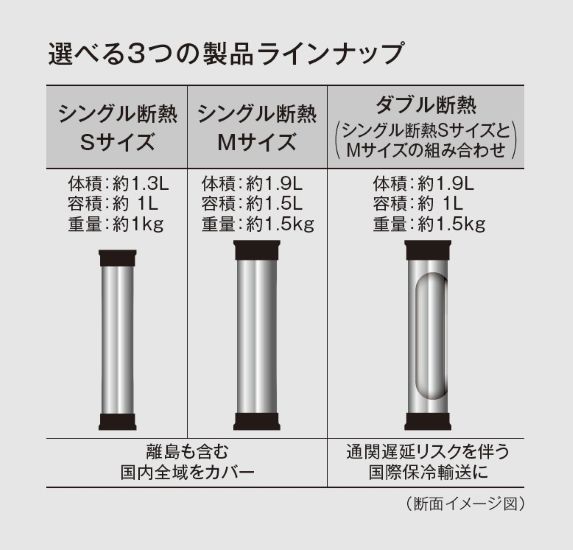

With three product lineups and various usage options, the BAMBOO SHELLter offers a new solution for the medical and pharmaceutical development fields.

It achieves what was previously difficult: a balance between reliable refrigerated transport without temperature excursions and low-cost shipping across all phases, from basic research to clinical trials and practice.

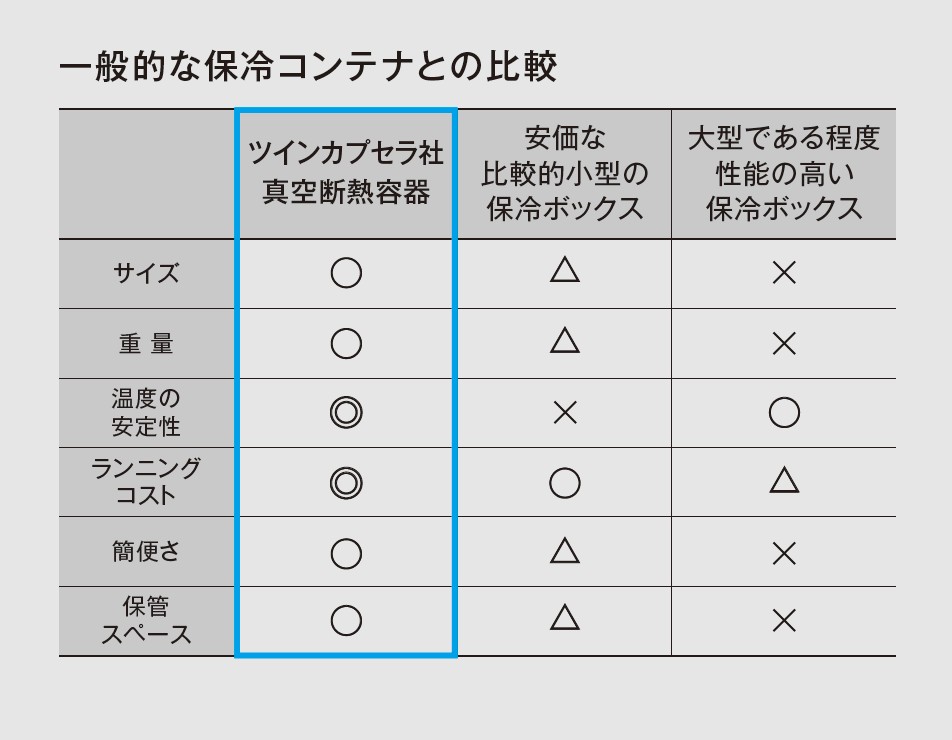

Many Advantages Over Traditional Cold Boxes

The smallest model, the Single-Insulation S size, has a volume of approximately 1.3L and weighs about 1kg. This makes it possible to ship using the most affordable “60 size” delivery service, leading to significant reductions in shipping costs compared to larger cold boxes.

Because the container maintains its own temperature, it can be shipped via standard courier services without the need for special refrigeration equipment. Its portable size and weight also make it convenient for hand-carrying during business trips or for temporary storage during house calls.

Furthermore, as it is battery-free, it is approved for air transport, giving it a wide range of advantages over many of the conventional cold boxes currently in use.

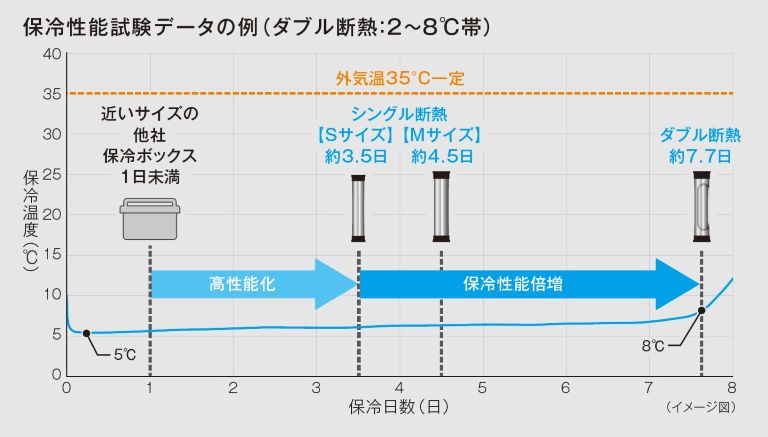

Exceptional Temperature Retention Performance

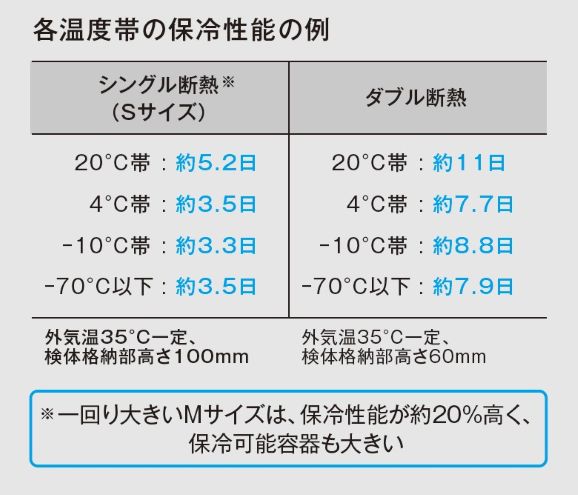

The BAMBOO SHELLter can maintain temperatures crucial to the biomedical field, including -70°C, -20°C, -10°C, 4°C, 20°C, and 37°C.

The Single-Insulation S size model can sustain these temperatures for over 3 days, while the Double-Insulation model can maintain them for over 7 days. Developed with high-performance vacuum insulation technology from space exploration, these containers minimize the impact of external heat, ensuring long-term, stable temperature retention. This significantly reduces the risk of damage from temperature excursions for sensitive biomedical materials like blood, cells, and biological tissues during transport.

Future Outlook and Expansion into Multiple Fields for Insulated Containers

Future Outlook and Expansion into Various Fields for Vacuum Insulated Containers

The innovative features and performance of the BAMBOO SHELLter have the potential to transform cold-chain logistics and the broader temperature-controlled

infrastructure of society. Its applications are wide-ranging and can be utilized in various settings within biomedical research institutions and medical facilities.

Basic & Clinical Research (Research Institutions, Biotech Ventures, etc.)

Reusable containers for samples and reagents shared with joint research partners

Sample collection for investigator-initiated (multi-center) studies

Clinical Testing (Testing Service Providers, etc.)

Transport of samples from medical institutions to testing centers

Sample collection from remote participants in decentralized clinical trials

Clinical Trials (Pharmaceutical Companies, CROs, etc.)

Transport of investigational drugs to medical institutions

Sample collection for international clinical trials

Pharmaceutical Supply (Pharmaceutical Wholesalers, etc.)

International transport of high-cost specialty drugs

Transport of small quantities of vaccines, etc.

Preservation and Supply of Biological Tissues (Biobanks, etc.)

Transport from medical institutions to biobanks

Transport from biobanks to medical and research institutions

Regenerative Medicine Research (Research Institutions, Bio-ventures, etc.)

Various types of transport in cell-based drug research and development

Round-trip transport of autologous cells to and from overseas processing facilities

Home-Visit Medical Care and Nursing (Home-Visit Medical Centers, etc.)

Temporary storage and shipment of specimens collected at the patient’s home

Transport of pharmaceuticals used at the home-visit site

Providing Medical Services to Remote Islands and Disaster Areas

Transporting pharmaceuticals and collecting specimens in remote areas

Transport via drones, where weight is a critical constraint

About JAXA Venture, “TwinCapsula Inc.”

TwinCapsula Inc. is a JAXA venture aiming for the social implementation of the insulation and cooling container technology from JAXA’s HTV Small Re-entry Capsule, under the slogan “Bringing the ‘Ultra’ Insulation and Cooling Technology of Re-entry Capsules to the Ground and into Society.”

By developing and supplying small, ultra-high-performance insulated containers, the company aims to enable personalized cold chain transport of specimens, vaccines, pharmaceuticals, biological tissues, and more. This will lead to the creation of new services in the biomedical transport field, including clinical testing, early screening for diseases like cancer, and decentralized clinical trials (DCT).

Official Website of TwinCapsula Inc.: https://twincapsula.co.jp/

Related Links

About Vacuum Insulation Technology>

What is “Vacuum Insulation Technology,” a core competence of Tiger Corporation?

Stainless Steel Vacuum Insulated Containers>

Introducing the mechanism and features of Tiger’s stainless steel vacuum insulated containers, which are also used in space development and the medical field.