Case Studies of Industrial Equipment Solutions

Vacuum-Insulated Double-Walled Container for Launch and Recovery of Space Experiment Samples

A reusable vacuum-insulated container for the two-way transport of JAXA’s space experiment samples between the ground and the ISS.

It is carried aboard SpaceX’s Dragon spacecraft and is used as Japan’s unique cold-chain transportation method to the ISS.

Background of the Development of the Vacuum-Insulated Container for Space | The Temperature Control Mission We Faced Again with JAXA

In November 2018, through a joint development with JAXA (Japan Aerospace Exploration Agency), our company successfully developed a vacuum-insulated double-walled container for space transport, which corresponded to Japan’s first challenge: a ‘technology demonstration for recovering experiment samples from the International Space Station (ISS) to Earth.’ This insulated container was mounted on the small recovery capsule of the H-II Transfer Vehicle ‘Kounotori’ 7, and was required to maintain a temperature of 4℃ ± 2℃ for more than 4 days while withstanding a landing impact of up to 40G.

Our company cleared these strict conditions with the cold-chain technology we have cultivated over 100 years.

This container proved its performance in the technology demonstration and advanced to the next development phase.

In the subsequent second phase, a more advanced temperature control mission was assigned as a further technical challenge: maintaining a temperature of 20℃ ± 2℃ for more than 12 days for protein samples during two-way transport to and from the International Space Station (ISS).

Our company began developing a new vacuum-insulated double-walled container.

New Challenges Required for the Vacuum-Insulated Container for Space

In developing the vacuum-insulated double-walled container for two-way transport to and from the International Space Station (ISS), advanced temperature control performance exceeding the previous technical achievements, lightweight and compact design, and reusability were required as new development requirements.

■Three Requirements Set for Phase 2:

Strict Temperature Management

To maintain the temperature of experiment samples from launch to the ISS, a coolant was included to keep the temperature at 20°C ± 2°C for more than 12 days.

Significant Weight and Size Reduction

While maintaining the high-performance insulation of the vacuum-insulated technology, the container was to be manufactured with a total mass of 4.7 kg or less

(including the coolant) and a compact size.

Design for Multiple Uses

To allow for long-term use, the container was designed to be reusable for more than 3 years or 6 times, rather than being a single-use product.

Solution to the Challenges

In collaboration with JAXA and Technosolva Inc., we proceeded with the design and improvement of a vacuum-insulated container for space transport that could maintain a stable temperature for an extended period.

As a result, through multiple temperature experiments, we successfully maintained a temperature of 20°C ± 2°C for 15 days and 7 hours.

Furthermore, we significantly reduced the total mass from the target of 4.7 kg to approximately 2.9 kg, contributing to improved efficiency in space transport.

Additionally, to enable multiple uses, we designed the vacuum-holding and vacuum-maintaining components to a higher standard than typical commercial products.

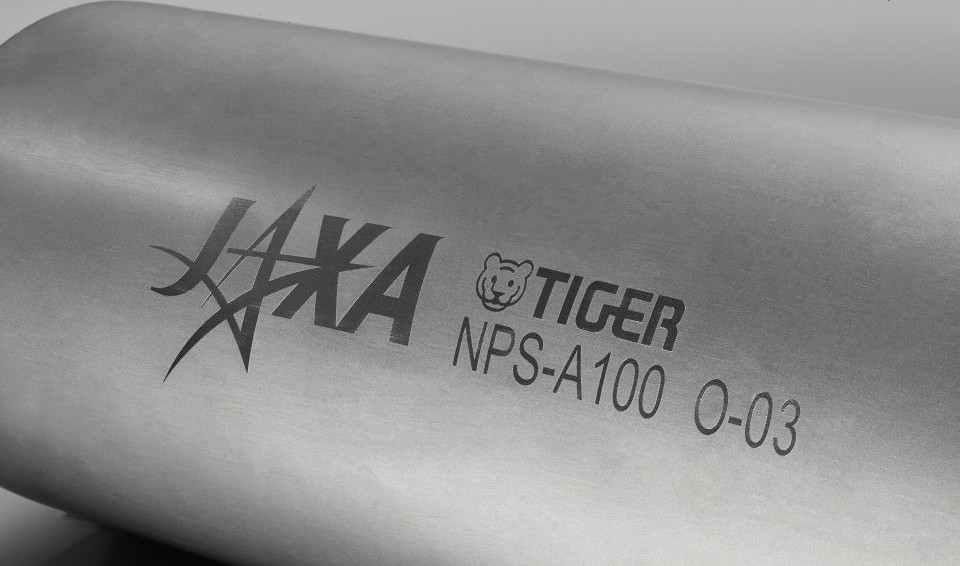

▼ Comparison with the NPL-A100 Vacuum-Insulated Double-Walled Container (Right), Delivered in 2018

(Left) NPS-A100

Total Mass: Approx. 2.9 kg

Outer Diameter: Approx. 130 mm

(Right) NPL-A100

Total Mass: Approx. 10 kg

Outer Diameter: Approx. 290 mm

Vacuum-Insulated Container That Supported a Space Experiment Returns Safely from the ISS

In December 2021, a vacuum-insulated container holding samples for a protein crystal space experiment was launched to the International Space Station (ISS) aboard SpaceX’s Dragon 24 cargo resupply mission. After a roughly one-month experiment period, the container returned to Earth in January 2022.

The internal temperature remained stable within the specified range for both the outbound and return journeys. The container is now in repeated use as a reusable cold-chain container for transporting materials between Earth and space.

Vacuum Insulation Technology’s Challenge for a Sustainable Future

For our vacuum-insulated bottles, our company has upheld ‘four promises’ since 2020—’NO conflict minerals,’ ‘NO fluorine coating,’ ‘NO subcontracting

all production,’ and ‘NO plastic waste’—as we take on social challenges related to human rights, health, and the environment for the future of our planet.

Aiming to create a sustainable society, we also launched an initiative in July 2021 to collect and recycle used stainless steel bottles.

Regarding this container, we participated in its design and development to be multi-use, driven by our desire to contribute to sustainable initiatives in

the space sector. We will continue to improve our core vacuum insulation technology and strive to realize a sustainable society.

Related Links

About Vacuum Insulation Technology>

What is “Vacuum Insulation Technology,” a core competence of Tiger Corporation?

Stainless Steel Vacuum Insulated Containers>

Introducing the mechanism and features of Tiger’s stainless steel vacuum insulated containers, which are also used in space development and the medical field.

その他の導入事例

Catalog

産業機器ソリューションに関する

お問い合わせ

開発・研究、真空断熱技術の応用方法、

弊社との協業に関するご相談、

お問い合わせはこちらから。