Newsletter

Tiger Corporation Reduces CO₂ from Refrigeration by 45.9% with Newly Developed Vacuum Insulation Panel

Contributing to decarbonization with new technology, also used at the Osaka-Kansai Expo, that consolidates over 100 years of vacuum insulation expertise

Tiger Corporation (President: Yoshiaki Kikuchi, Headquarters: Kadoma City, Osaka), a world leader in thermal control technology, conducted a demonstration experiment with a reefer container (refrigerated container) equipped with its proprietary “Stainless Steel Sealed Vacuum Insulation Panel TIVIP,” and succeeded in reducing power consumption and CO₂ emissions by 45.9%*. This technology is also being utilized for transportation inside and outside the venue of the Osaka-Kansai Expo in the form of transport boxes, contributing to the realization of a decarbonized society.

By using stainless steel, the “Stainless Steel Vacuum Insulation Panel TIVIP” has made it possible to maintain non-combustibility and high insulation performance over a long period, which was not achievable with conventional non-stainless steel vacuum insulation materials. When used in refrigerated transport containers and building materials, it reduces the need for electrical energy to maintain temperatures, making it a sustainable, environmentally friendly material that contributes to CO₂ reduction.

Demonstration experiment achieves a 45.9% reduction in CO₂ emissions with “TIVIP” installation

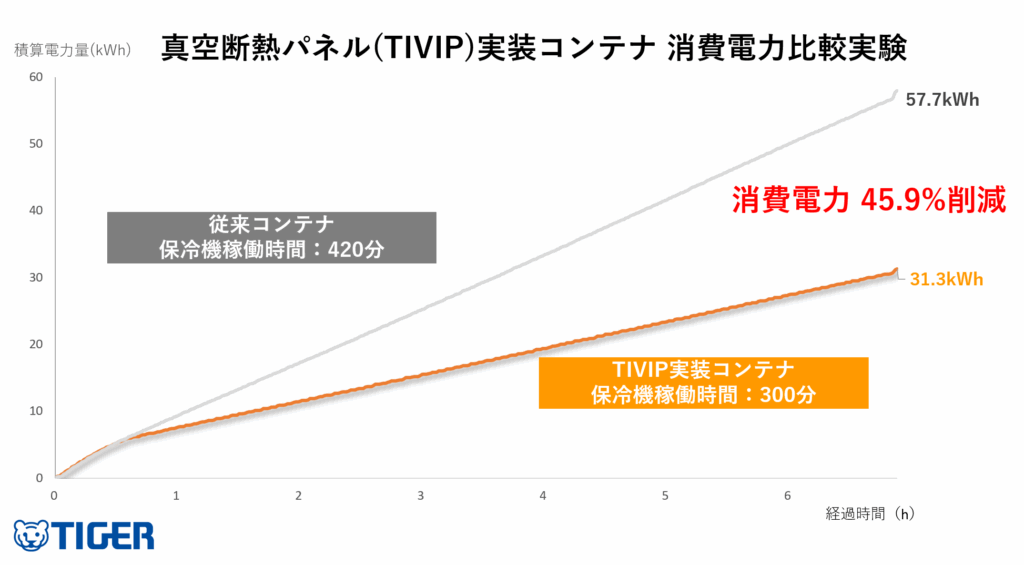

In Kobe City, Hyogo Prefecture, on a summer day with an average temperature of 32.3 degrees Celsius, an experiment was conducted to measure the power consumption of a container with TIVIP installed and a conventional reefer container over 7 hours. With the cooler set to maintain an internal temperature of 5°C, the cooler in the conventional container ran continuously for the entire 7 hours (420 minutes). In contrast, the high insulation capacity of the TIVIP-equipped container reduced the cooler’s operating time to 5 hours (300 minutes), securing a total of 120 minutes of non-operating (OFF) time. This superior insulation performance achieved a 45.9% reduction in power consumption and CO₂ emissions.

*Result of a demonstration experiment conducted on July 28, 2025, in an environment with an average temperature of 32.3°C. (Refrigeration condition set to 5°C, measured for 7 hours).

Utilized at the Osaka-Kansai Expo. Contributing to solving issues in the logistics industry.

This technology was also adopted for insulated boxes to transport food ingredients to restaurants from inside and outside the Osaka-Kansai Expo venue. Because it can maintain temperature without a power source, it enables the transport of frozen and refrigerated goods on standard trucks, as well as “consolidated transport” of cargo requiring different temperature zones simultaneously.

Enabling consolidated transport reduces the number of trucks needed, which leads to lower CO₂ emissions and helps solve labor shortages.

Comment from our collaborative partner: Mr. Takanori Kurata, Nippon Express Co., Ltd.

The vacuum insulation panel has an extremely high insulation effect, and the “Protect BOX Thermal” which is equipped with this panel has already received inquiries from the semiconductor, pharmaceutical, and food industries. We believe it will be utilized in an even wider range of industries in the future. We have high expectations that it will expand the possibilities for logistics, as it can support environmentally friendly transport. We are also conducting heat-retention transport experiments in the winter, aiming to provide it as an eco-friendly transport solution that can be used throughout the seasons.

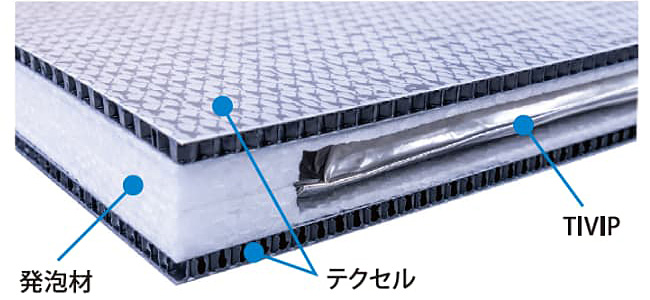

Reference: Features of the Stainless Steel Sealed Vacuum Insulation Panel (TIVIP)

This is a high-performance insulation material that minimizes thermal conductivity by creating a vacuum inside the panel. Compared to other common insulation materials, it demonstrates a high insulation effect even when very thin.

Due to this characteristic, it is expected to be used in fields that prioritize energy savings and space efficiency. Furthermore, the use of stainless steel makes it possible to achieve non-combustibility and maintain high insulation performance over a long period, which was not possible with conventional non-stainless steel vacuum insulation materials.

The Stainless Steel Sealed Vacuum Insulation Panel, with its outstanding insulation performance, is expected to be utilized in various industrial fields. It will particularly contribute to the next generation of technological innovation in the transportation and construction/building material sectors, where energy efficiency and temperature control are required.

Reference: About collaborative partners in the demonstration experiment at the Expo

For its use at the Osaka-Kansai Expo, our newly developed stainless steel sealed vacuum insulation panel “TIVIP” is sandwiched with “TEXEL,” a lightweight, high-strength resin honeycomb panel from Gifu Plastic Industry Co., Ltd. This protects the TIVIP and creates a lightweight yet strong insulated unit panel.

By incorporating this insulated unit panel into products like Nippon Express’s transport packaging tool, the “Protect BOX Thermal,” high-performance refrigerated transport has become possible. While conventional frozen, refrigerated, and constant-temperature transport required the use of cold or heat storage materials to maintain temperature, this new technology eliminates the need for such materials and achieves a significant reduction in power consumption.

Related Links

About Vacuum Insulation Technology>

What is “Vacuum Insulation Technology,” a core competence of Tiger Corporation

Stainless Steel Vacuum Insulation Panel TIVIP>

Learn about the mechanism and features of Tiger’s Stainless Steel Vacuum Insulation Panel. With its high thermal insulation, long lifespan, and non-flammability, it is expected to play a major role in the transportation and building materials industries

Catalog

About Industrial Equipment Solutions

Contact Us

For more information, contact us from here;

On research and development, methods of applying vacuum insulation technology,

and inquiries about partnership