Event Report

New cold chain transport equipment featuring the Stainless Steel Vacuum Insulation Panel, TIVIP, has been publicly unveiled,

having started operations at the Osaka-Kansai Expo venue.

From May 27, 2025, it will be used for temperature-controlled transport within the Osaka-Kansai Expo venue.

For the first time, we are unveiling refrigerated/frozen containers (reefer containers) and insulated boxes that feature our newly developed “Stainless Steel Vacuum Insulation Panel, TIVIP.”

A joint press conference was held with Nippon Express and Gifu Plastic Industry, who were involved in the development.

Norifumi Minamimura of Tiger Corporation, and Mr. Takanori Kurata of Nippon Express.

On Wednesday, May 28, 2025, Tiger Corporation, a world leader in thermal control technology, held a joint media briefing with Nippon Express Co., Ltd. and Gifu Plastic Industry Co., Ltd. The briefing was held to announce the use of a new cold-chain transport system that has begun operations at the Osaka-Kansai Expo venue. The system utilizes a newly developed Stainless Steel Sealed Vacuum Insulation Panel (TIVIP).

To address the challenges of temperature management and energy efficiency in the logistics industry, Tiger Corporation has developed a new solution based on next-generation insulation technology. The company is currently conducting demonstrations for its newly developed Stainless Steel Vacuum Insulation Panel (TIVIP).

Of the cold chain transport equipment under development and demonstration, the items unveiled on this occasion are the vacuum insulated roll box and vacuum insulated protect box (“Protect BOX Thermal”) that began operation at the Osaka-Kansai Expo venue on May 27, 2025, and the vacuum insulated reefer container (refrigerated/frozen) whose future introduction is being considered.

During the Expo demonstration, temperature data is being acquired and analyzed, with the goal of commercializing the Protect BOX Thermal in fiscal year 2026.At the briefing, Tiger Corporation, along with Nippon Express and Gifu Plastic Industry, each presented their strategies for addressing industry challenges, highlighting the technology’s key features and future outlook.

This transport equipment is expected to be deployed in a wide range of fields, including food, pharmaceuticals, electronic components, and art.

Demonstration Cases at the Expo ② and ③ began use on May 27, 2025.

① Vacuum Insulated Reefer Container

For outdoor installation (storage)

Comparing power consumption (to visualize energy savings) and carbon dioxide emissions with and without the addition of the stainless steel sealed vacuum insulation panel.

② Vacuum Insulated Protect Box

“Protect BOX Thermal”

For transport inside/outside the venue

Utilizing Vacuum Insulated “Protect BOX” (Protect BOX Thermal) for refrigerated cargo transport to pavilions, restaurants, and other facilities within the Expo venue.

③ Vacuum Insulated Roll Box

For transport inside/outside the venue

Utilizing Vacuum Insulated Roll Boxes for refrigerated cargo transport to pavilions, restaurants, and other facilities within the Expo venue.

Scenes from the Media Briefing

On the Trends and Challenges in the Logistics Industry: Mr. Takanori Kurata, Nippon Express Co., Ltd.

Following the pandemic, the logistics industry has seen a sharp increase in demand for home deliveries due to the expanding

e-commerce market. This has created a challenge in streamlining small-lot and last-mile deliveries.

In addition, a severe labor shortage of drivers and warehouse workers is accelerating the adoption of automation,

including the introduction of automated warehouses, robots, and AI.

Furthermore, the industry is also accelerating its sustainability efforts, including the promotion of logistics DX aimed at improving operational efficiency and cutting costs, as well as the adoption of EV trucks. Other major challenges include the “2024 Logistics Problem,” which stems from stricter labor regulations that took effect in April 2024, and the restructuring of global supply chains in response to geopolitical risks.

Mr. Kurata announced that, against this backdrop, the entire industry is accelerating the pace of change and advancing a wide range

of initiatives.

An Explanation of the Vacuum Insulation Panel by Norifumi Minamimura, Tiger Corporation

Tiger Corporation is leveraging its vacuum insulation technology, cultivated over 100 years, to drive the development of the Vacuum Insulated Panel (TIVIP), with the goal of contributing to global warming prevention and carbon neutrality.

Unlike conventional materials, the adoption of stainless steel has enabled the panel to achieve high thermal insulation, a long lifespan,

and non-flammability. Consideration for its expansion into reefer containers, transport boxes, and building materials is underway,

and the new material is attracting attention for its superior energy-saving, safety, and recyclability features.

Mr. Minamimura announced that the company aims to expand the introduction of the panel into the logistics and construction sectors

in the future.

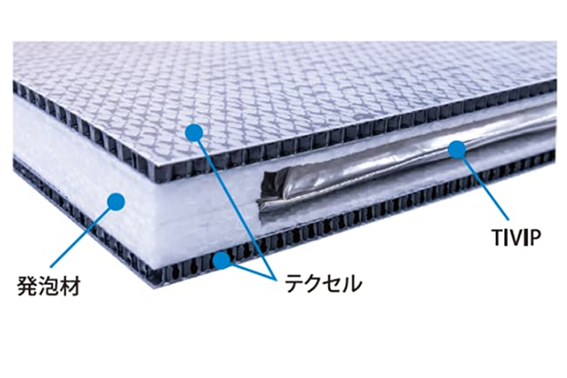

An Explanation of Teccell by Mr. Masato Iwai, Gifu Plastic Industry Co., Ltd.

Developed by Gifu Plastic Industry Co., Ltd., the resin-based honeycomb panel Teccell is a hollow structure with excellent lightness

and strength, which utilizes a polypropylene honeycomb.

Because of its unique properties, it is used in a wide range of fields, including automobile interiors, logistics materials, sound-absorbing panels, building materials, furniture, and shock-absorbing materials.

Mr. Iwai announced that the company is expanding its applications to include office booths, flooring for sports facilities,

soundproofing measures, and protectors, leveraging its lightweight, high-strength, and versatile properties.

Practical Operations and Future Vision at the Expo by Mr. Takanori Kurata, Nippon Express Co., Ltd.

At the Expo, starting on May 27, 2025, the use of cold chain transport equipment with temperature-maintaining functions began for freight that requires temperature control, such as food, beverages, and souvenirs provided within the venue.

During transport, temperature data is being acquired and managed, and verification and analysis for future commercialization are also being carried out.

Mr. Kurata stated that with an eye toward commercialization in fiscal year 2026, the company is considering expansion into a wide range of fields such as food, pharmaceuticals, electronic components, and art, while also addressing challenges like suppressing temperature rise in the summer and preventing freezing in the winter.

Reefer containers (refrigerated and frozen) and insulated boxes that use Stainless Steel Vacuum Insulation Panels.

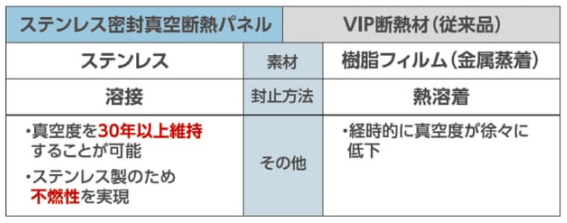

Features of the Stainless Steel Vacuum Insulation Panel (TIVIP)

Watch a video on the Stainless Steel Vacuum Insulation Panel here:

https://youtu.be/U-65yP4W-Ds

This is a high-performance insulation material that achieves extremely low thermal conductivity by creating a vacuum inside the panel. Compared to other conventional insulation materials, it provides a high thermal insulation effect even at a very thin thickness.

Due to these characteristics, its use is expected in fields that prioritize energy saving and space efficiency.

Furthermore, using stainless steel allows for the long-term maintenance of non-flammability and high thermal insulation, which was not

possible with conventional non-stainless vacuum insulation materials. Due to its outstanding insulation performance, the panel is expected to be utilized in a wide range of industrial fields. It will particularly contribute to next-generation technological innovation in the transport and construction industries, where energy efficiency and temperature management are essential.

Regarding Collaborative Partners for the Demonstration Experiment at the Expo

In the utilization at the Osaka-Kansai Expo, we are using a lightweight and robust insulation unit panel that sandwiches our newly developed Stainless Steel Vacuum Insulation Panel, “TIVIP,” between “Teccell,” a lightweight and high-strength resin-based honeycomb panel from Gifu Plastic Industry.

By adopting this insulation unit panel in Nippon Express’s transport and packaging tools, such as the Protect BOX, we’ve enabled high-performance cold chain transport. While conventional frozen, refrigerated, and temperature-controlled transport required the use of coolants or heat storage materials to maintain temperature, our solution makes these materials unnecessary and achieves a significant reduction in electricity usage.

As a core company of the NX Group, Nippon Express provides high-quality, sustainable logistics solutions globally by making full use of air,

marine, rail, truck, warehousing, and IT. Furthermore, it is a “Recommended Logistics Provider” and a “Designated On-site Cargo Handling

Provider” for the Osaka-Kansai Expo.

They manufacture and sell plastic industrial materials, industrial parts, and medical parts, as well as daily household goods and water pipe joints.

They have also commercialized TECCELL, an excellent next-generation honeycomb core material with very high specific strength and specific stiffness. In the logistics field, TECCELL is poised to pursue limitless possibilities.

Also Scheduled for Exhibition at the “Future Life Experience” within the “Future Society Showcase Project”

Our “Stainless Steel Vacuum Insulation Panel Technology” is being developed and demonstrated with support from the Osaka Prefectural Government. This falls under their “Carbon Neutral Technology Development and Demonstration Project,” a program that backs companies creating cutting-edge solutions to contribute to carbon neutrality.

A portion of this technology will be exhibited at the 2025 Japan International Exposition from October 7 to October 13, 2025.

It will be featured as part of the “Future Life Experience” within the “Future Society Showcase Project.”

Date: October 7 (Tuesday) to October 13 (Monday), 2025

Location: Inside the Expo venue (West Entrance Plaza side), at the “Future Life Experience” within the “Future Life Village”

Exhibition Content: Tiger Corporation’s Stainless Steel Sealed, Long-lifespan, Non-flammable Vacuum Insulation Panel Technology Development and Demonstration

*This will be a joint booth with other companies participating in the “Carbon Neutral Technology Development and Demonstration Project.”

About Tiger Corporation

Founded in 1923 with the manufacturing of a glass thermos for the domestic Japanese market under the “Tiger” brand, we have pursued technology related to “temperature” for 100 years, aiming to realize our Vision to “spread happy family gatherings throughout the world.

By applying our core Vacuum Insulation Technology and Heat Control Technology, we manufacture and sell household and commercial vacuum insulated containers (thermoses) like our vacuum insulated bottles, as well as cooking appliances such as rice cookers. We also manufacture and sell industrial parts and products for a wide range of fields, including transportation, construction, space, and medicine, operating in over 60 countries worldwide.

Related Links

About Vacuum Insulation Technology>

What is “Vacuum Insulation Technology,” a core competence of Tiger Corporation?

Stainless Steel Vacuum Insulation Panel TIVIP>

Learn about the mechanism and features of Tiger’s Stainless Steel Vacuum Insulation Panel. With its high thermal insulation, long lifespan, and non-flammability, it is expected to play a major role in the transportation and building materials industries

【Media Feature】 A case study on the application of our Stainless Steel Vacuum Insulation Panel was featured on TV Tokyo’s “World Business Satellite.”

You’ll be redirected to the TV Tokyo BIZ YouTube channel.

https://www.youtube.com/watch?v=9XeajF1y7lA

Catalog

About Industrial Equipment Solutions

Contact Us

For more information, contact us from here;

On research and development, methods of applying vacuum insulation technology,

and inquiries about partnership