Development Episode: Industrial Equipment Solutions

[Tiger Corporation × JAXA Startup] Solving the “Last Mile” Challenge in Medical Transport. The Development Story of “BAMBOO SHELLter,” Achieving Over 11 Days of Cold Storage Without Power

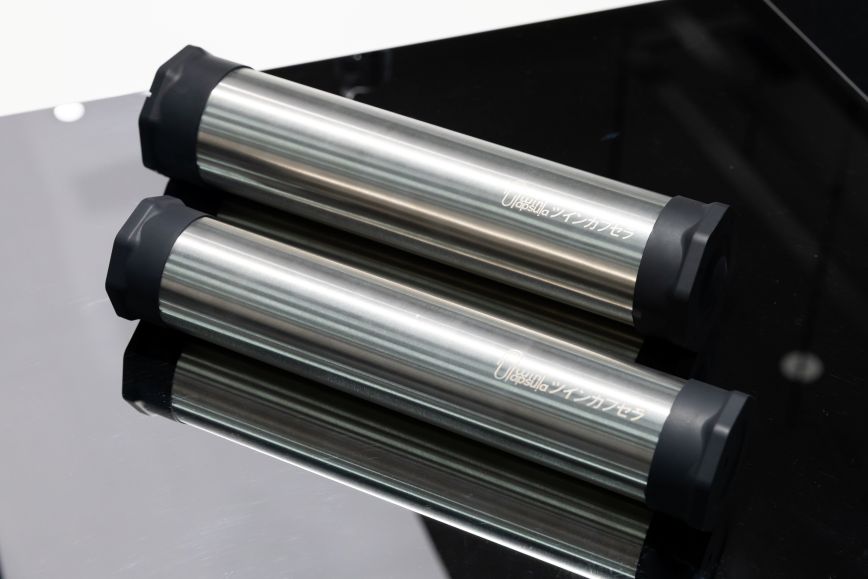

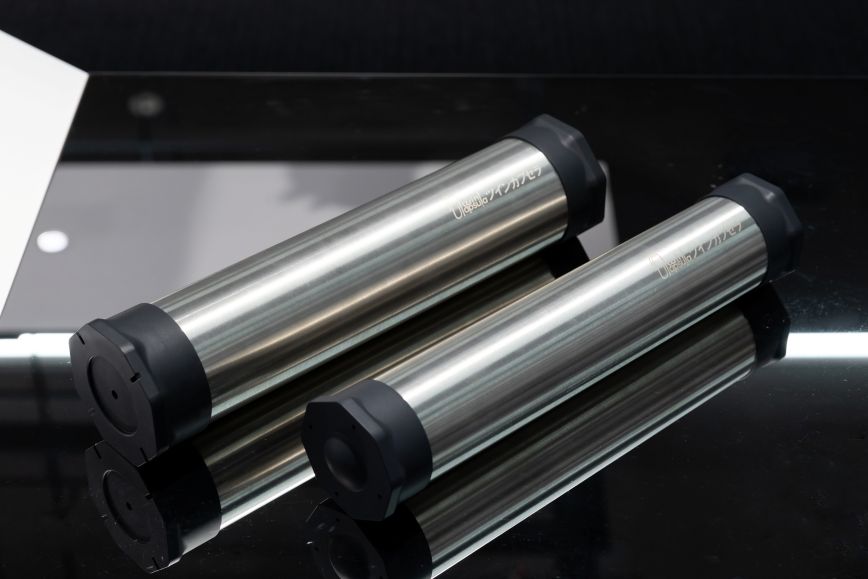

In February 2025, Twincapsula Inc., a JAXA-certified startup, released its first product: the “BAMBOO SHELLter,” an ultra-insulated cold storage container. This compact, high-performance container, a culmination of the company’s space-related technology and Tiger Corporation’s vacuum insulation technology, solves challenges related to temperature deviation risks, costs, and labor in the transport of pharmaceuticals and specimens. It enables long-term cold storage (for a maximum of over 11 days) across various temperature ranges, from -70°C to near body temperature, without the need for a power source. Twincapsula CEO Kazuhiro Miyazaki, who led the development, and Norihito Minamimura, Manager of the Product Planning Section 2 Team in the Solution Group at Tiger Corporation, look back on the journey from their first meeting to the development and commercialization of the “BAMBOO SHELLter.”

JAXAでの回収カプセルプロジェクトの成功を機に協力体制を構築

Minamimura: Please tell us about the history behind the launch of Twincapsula.

Miyazaki: In 2018, as a member of the Small Recovery Capsule project to retrieve space experiment samples from the International Space Station (ISS) in a refrigerated state, I was involved in developing a double-walled vacuum insulated container. The technology demonstration for Japan’s first refrigerated retrieval from the ISS, which we challenged in this project, was extremely successful. I wanted to apply the insulated refrigeration technology developed by JAXA to solve problems on the ground, so in 2021, I established Twincapsula Inc. as a JAXA startup to conduct business utilizing JAXA’s technology.

Minamimura: I heard that the joint development of the BAMBOO SHELLter with our company was sparked by that project. What was your original impression of Tiger Corporation?

Miyazaki: During the recovery capsule project, as a JAXA engineer, I asked if you would be willing to cooperate in the research and development of an insulated container for the capsule. Despite the short timeframe and the risks involved in the mission, you quickly responded with “Let’s do it” and completed the prototype within the deadline. There’s an article about this on the JAXA website (*), and because of this, I had the impression that your company is proactive about taking on technological challenges.

*For more information on the collaboration with Tiger Corporation in JAXA’s recovery capsule project, please see here:

Japan Aerospace Exploration Agency (JAXA) Institutional Magazine [JAXA’s], P12-13.

Minamimura: It was certainly a difficult mission, but being involved in space-related development was exciting. I feel it was a good breakthrough, both technologically and mentally. What are your thoughts on the vacuum insulation technology we collaborated on this time?

Miyazaki: I understand that vacuum insulation is particularly high-performing among insulation materials, and it’s a spatially efficient technology because it provides high insulation performance even when thin. Just as with the recovery capsule, which had strict spatial constraints, it was an indispensable technology to realize the “compact, high-performance insulated container” that our company aimed for with the development of BAMBOO SHELLter.

Minamimura: Thank you. After you founded Twincapsula Inc., we formed a business partnership. Why did you reach out to Tiger Corporation again after establishing Twincapsula?

Miyazaki: Although Twincapsula inherited technology from JAXA, developing a new product required further technological challenges. Therefore, I wanted to borrow the strength of Tiger Corporation, with its high level of technology and proven track record. Also, the relationship of trust we built while working together at JAXA made it easy for me to ask with confidence.

Overcoming Challenges in Cost, Labor, and Cold-Storage Performance by Leveraging Tiger Corporation’s Technology

Minamimura: What are the current challenges in the market surrounding refrigerated transport in the biomedical field?

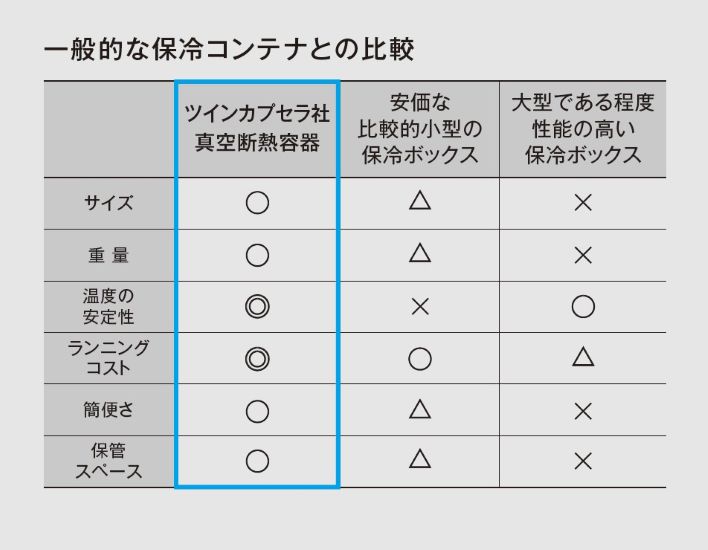

Miyazaki: In the refrigerated transport of specimens, pharmaceuticals, and biological tissues, maintaining temperature is extremely important to ensure safety and the reliability of tests. If a temperature deviation occurs, it not only causes financial loss but also potentially damages precious, priceless specimens and biological tissues. To ensure reliable refrigerated transport, even for a small quantity, it is necessary to use large insulated boxes with a large amount of refrigerant and hire a specialized company for chartered transport, which incurs high costs. On the other hand, inexpensive shipping services like courier delivery always come with the risk of temperature deviation. Therefore, we see it as a challenge that reliability and low cost cannot coexist in small-volume refrigerated transport.

Minamimura: The transportation of pharmaceuticals also became a hot topic with the COVID-19 vaccine, didn’t it? The “BAMBOO SHELLter” is meant to solve these issues, but could you tell us again about its performance and features?

Miyazaki: Its greatest feature is being “compact and high-performance.” Generally, the cooling performance of an insulated box is proportional to its size, so a compact, ultra-high-performance refrigerated container is something that has never existed before. The ability to achieve high cooling performance despite its small size was largely due to our collaboration with Tiger Corporation, which has advanced technology and experience in insulated containers.

When transporting blood, for example, it is necessary to maintain the temperature stably and reliably within a required range, such as 18-25°C or 2-8°C. The temperature inside the “BAMBOO SHELLter” is set according to requirements by changing the refrigerant inside. For a small container, it is necessary to maintain the temperature for a long period with a small amount of refrigerant, so high insulation performance is extremely important to make the refrigerant last longer. In that sense, being able to provide several days of refrigeration with only about 400g of refrigerant is a considerable advantage.

In fields like regenerative medicine, there is a need to transport cells while they are still alive. To accommodate this, the temperature can be set close to body temperature. By using dry ice instead of refrigerant, we can also meet the need to “transport cells in a frozen state” at -70°C or below.

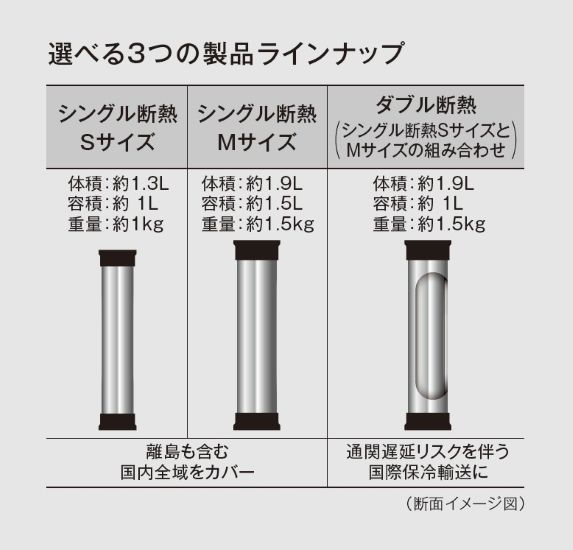

The “BAMBOO SHELLter” lineup includes three types: “S size,” “M size,” and “Double Insulation.” At major temperature ranges, the S size can maintain its temperature for about 3 days or more, the M size for about 4 days or more, and the Double Insulation for about 7 days or more.

Many people use the S size when transporting one to a few specimens, and the M size is often used for transporting around 10 specimens at once. The Double Insulation has the same volume as the S size but can maintain its temperature for over a week (up to 11 days or more depending on the temperature range), making it suitable for international transport where there is a high risk of customs delays.

Minamimura: So it can also be used for overseas transport. If compact and reliable refrigerated transport is possible, it seems like it could also solve the last-mile problem that is a challenge in the cold chain.

Miyazaki: Yes, that’s right. This container is like a small refrigerator/freezer, so once you put things inside, you don’t need refrigerated facilities or vehicles for transport. You can ship it from the sender to the destination via standard room-temperature delivery while maintaining refrigeration throughout. For remote islands, it’s fine to have a transport leg using a small, non-refrigerated drone. In that sense, it can be said that it covers not only the last mile but also the sender’s so-called “first mile.”

Minamimura: I see. That’s amazing. Were there any special considerations during development?

Miyazaki: The key is its long, thin shape, like bamboo, as the name BAMBOO SHELLter suggests. Heat enters an insulated container through the uninsulated opening, so we made the shape thin to reduce the area of the opening. In addition, by storing the items to be refrigerated at the very back of the long, thin container and placing the refrigerant at the entrance side, we have achieved long-term temperature maintenance. In addition to the innovative shape, the vacuum insulation itself is of high quality thanks to Tiger Corporation’s technology.

During development, we received various pieces of advice from Tiger Corporation, and we also made many technologically difficult requests, but I believe we were able to bring our ideas to life thanks to the technology and know-how that Tiger Corporation has cultivated.

Minamimura: Thank you. On the other hand, were there any difficulties?

Miyazaki: The main point was how to balance the contradictory features of “compact” and “high-performance.” To cover the entire country, including remote areas, with refrigerated courier services, we set a development target of “a minimum of three days” of cooling performance for each temperature range.

We could extend the cooling time by increasing the size, but that would go against the concept of “compact and high-performance.” Therefore, we aimed for a size that would fit within the 60-size category (total of length, width, and height of 60 cm or less), which is the minimum fee category for courier services. As a result, the S-size container fits perfectly into the 60-size, and its design maximizes the “cost-performance of refrigeration,” which is the cooling capacity divided by the transport cost.

Minamimura: I imagine you run various simulations during the development process. Has the gap between simulation and actual measurement data been eliminated at this point?

Miyazaki: Yes, although we had a foundation in simulation technology from our development experience at JAXA, Twincapsula has also established simulation technology specialized for insulated containers, and we are now able to predict performance through numerical analysis. When developing a new insulated container, it is ultimately necessary to verify its performance through prototyping and experiments, but repeating prototyping and testing many times increases development costs. Therefore, it is extremely important to be able to predict performance with high accuracy through simulation at the design stage. In the development of this BAMBOO SHELLter, we were able to use that simulation technology to develop a product that achieved the target performance in a short period.

Anticipating Use in the Biomedical Field. Eyeing Overseas Expansion as Well

Minamimura: In what fields would you like to see the “BAMBOO SHELLter” utilized?

Miyazaki: We would like it to be useful in the biomedical field, for pharmaceutical companies, testing centers, and research institutions such as universities. We also believe it can be widely used in various phases, including basic research, clinical trials, and clinical practice. Currently, our focus is on Japan, but in the future, we would like to expand its use overseas and for international transport across borders. For example, we believe there is strong demand in hot regions like Asia and Africa, especially in areas where the cold chain is not well-established.

Minamimura: It’s true that since it doesn’t use electricity for refrigeration, it can be used anywhere in the world. Have you received any feedback from actual users?

Miyazaki: For example, someone from a blood testing company commented, “The temperature of specimens transported with the ‘BAMBOO SHELLter’ is stable, so we are grateful that we can perform high-quality tests.” Also, a researcher who uses it for transport to an overseas joint research partner commented, “I was worried because it took a long time to clear customs, but the temperature was maintained without any problems.” I’m very happy that the value we envisioned is being properly delivered to our customers.

Minamimura: Do you have a message for those who are considering introducing high-performance containers in the medical transport field?

Miyazaki: The “BAMBOO SHELLter” is an unprecedented product and is not yet widely known, so it may be difficult to adopt it immediately. However, once people use it, they tend to like it and often make additional purchases or recommend it to others. We also offer free loans for trial use, so I would like people to first experience its amazing capabilities for themselves.

Minamimura: Finally, please tell us about your future vision and the role you want to play in society.

Miyazaki: Starting from research and development at JAXA, we were able to achieve the commercialization we aimed for with the support of many people. In the biomedical field, many companies, research institutions, and medical institutions are engaged in research activities that create new value, as well as medical activities that protect health and life. We want to contribute by supporting these efforts with our products and services. Also, we have ideas for further improving the “BAMBOO SHELLter,” so we would definitely like to continue to receive cooperation from Tiger Corporation in the future.

Minamimura: Our company also wants to actively take on challenges in the B2B and industrial equipment fields, in addition to cooking appliances and vacuum bottles for general households. I believe the “BAMBOO SHELLter” will become a core product in that effort, and I look forward to our continued partnership.

Twincapsula Inc. Website

https://twincapsula.co.jp/product/bamboo_shellter.html

Tiger Corporation Industrial Equipment Solutions Page

https://www.tiger-corporation.com/ja/jpn/for-business

【Profiles】

Kazuhiro Miyazaki

President/CEO, Twincapsula Inc.

As a member of JAXA’s HTV-mounted Small Recovery Capsule project, he was in charge of developing the double-walled vacuum insulated container, payload interface, sample transport, and more. Feeling a desire to personally realize the potential of the technology he developed to benefit the world—a commercialization for terrestrial applications that was difficult for JAXA staff to lead—he established Twincapsula Inc. in 2021.

Norihito Minamimura

Manager, Product Planning Section 2 Team, Solution Group, Tiger Corporation.

As part of Tiger Corporation’s NEXT 100 challenge, he is working to expand business in the B2B and industrial equipment fields by applying and evolving the “vacuum insulation technology” and “heat control technology” cultivated over the years.

Product/Service Information

Vacuum-Insulated Stainless Container

A Vacuum-Insulated Stainless Container is a container with a vacuum layer between a double-walled structure to minimize temperature changes. This structure effectively suppresses heat conduction and convection to achieve high insulation performance. Vacuum insulated containers are used in various applications that require heat or cold retention.

Catalog

About Industrial Equipment Solutions

Contact Us

For more information, contact us from here;

On research and development, methods of applying vacuum insulation technology,

and inquiries about partnership