Development Episode: Industrial Equipment Solutions

Secrets to the Birth of TIGER’s Newly Developed Insulating Material: The “TIVIP” Stainless Steel Vacuum Insulation Panel

Tiger Corporation, a long-established manufacturer of vacuum bottles, is embarking on a new challenge for its 100-year history by refining its “vacuum insulation technology.” Here are the secrets behind the birth of TIVIP, the newly developed stainless steel sealed vacuum insulated panel that contributes to reducing CO2 emissions.

Founded in 1923, Tiger Corporation started by manufacturing “Torajirushi” (Tiger Mark) glass vacuum bottles for the Japanese market.

Through a century of creative innovation and dedicated craftsmanship, we have transformed vacuum bottles from luxury items into everyday household necessities.In February 2023, we celebrated our 100th anniversary.

Today, we continue to create products using two core technologies: vacuum insulation technology, best seen in our vacuum-insulated bottles, and heat control technology, which began with the development of our first electronic rice cooker in 1970.

With these technologies, we strive to achieve our vision of “”Spreading joyous harmony throughout the world.

Currently, Tiger Corporation’s products, including vacuum-insulated bottles and cooking appliances like rice cookers, are sold in over 60 countries. Additionally, the company manufactures and sells industrial parts and products for sectors such as transportation, construction, aerospace, and medical fields.

TIGER’s new venture, the stainless steel vacuum insulation panel, is a challenge for the company’s next 100 years.

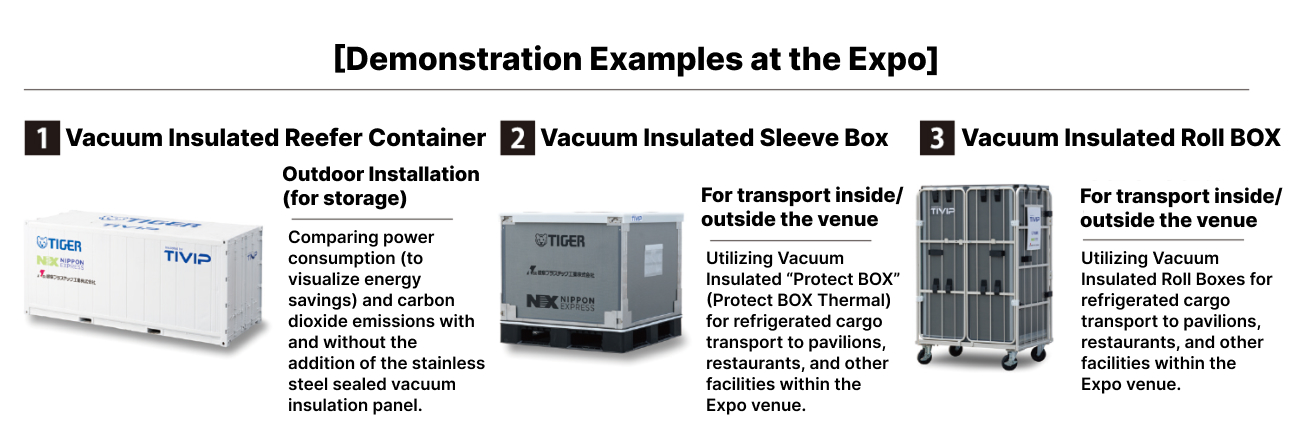

This innovative insulation material is expected to contribute to a wide range of fields, especially the transportation industry, where reducing CO2 emissions is an urgent task for achieving a decarbonized society.This technology has also been selected for use in refrigerated transportation both inside and outside the venue for the EXPO 2025 Osaka, Kansai, Japan.

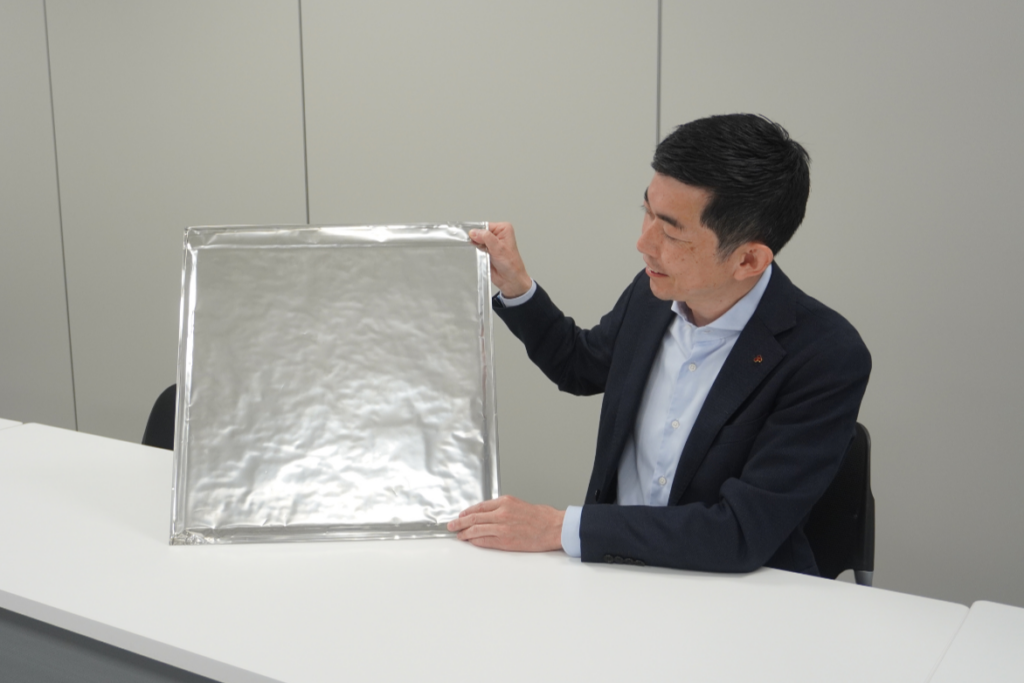

We spoke with Norifumi Minamimura, the project leader for the vacuum insulated panel, to uncover the secrets behind why Tiger Corporation, a long-standing manufacturer of vacuum-insulated bottles, decided to venture into developing Stainless Steel Vacuum Insulation Panels for the logistics and construction industries.

What is the Stainless Steel Vacuum Insulation Panel (TIVIP)?

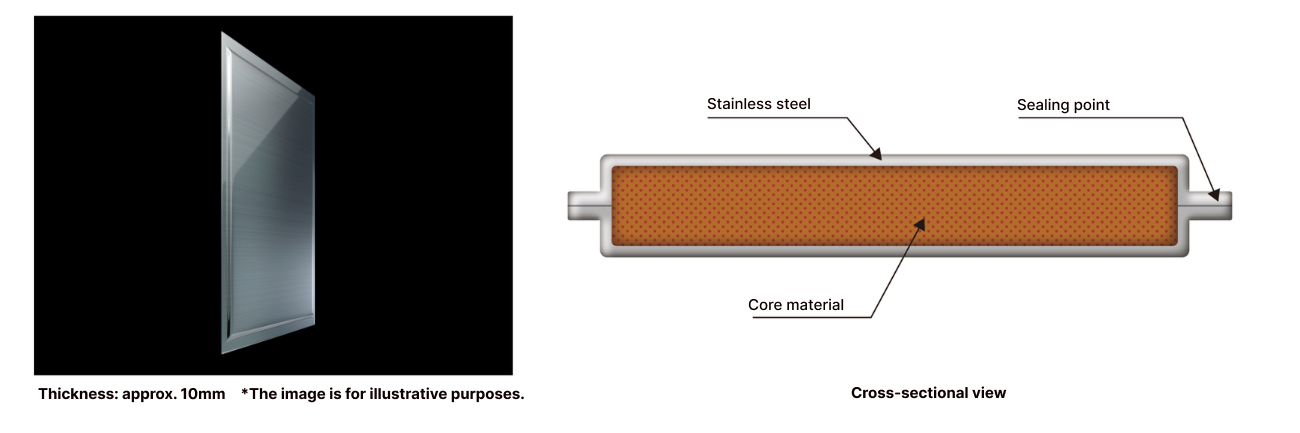

TIVIP is a high-performance insulation material that significantly reduces heat transfer by creating a vacuum inside the panel.

Compared to conventional insulation materials, it provides a high level of thermal insulation even at a very thin thickness.

This makes it ideal for applications where energy efficiency and space saving are critical. Thanks to the use of stainless steel, TIVIP achieves a level of fire resistance and long-lasting thermal performance that was not possible with traditional non-stainless vacuum insulation materials.

The Motivation for Development:

Our technology, refined through everyday vacuum-insulated bottles, is ready for industrial use.

We want to contribute to solving the problems of a warming world.

We at Tiger Corporation have cultivated vacuum insulation technology through over 100 years of developing and manufacturing

vacuum bottles. This technology, which allows for keeping things hot or cold without using electricity, is a simple yet infinitely promising technique. Not only is it gaining attention as a sustainable technology, but it also has the great advantage of being applicable regardless of location or environment.

Development continues in a variety of fields, and since 2018, we have been involved in space development by creating double-wall vacuum-insulated containers to transport valuable experiment samples from the International Space Station.

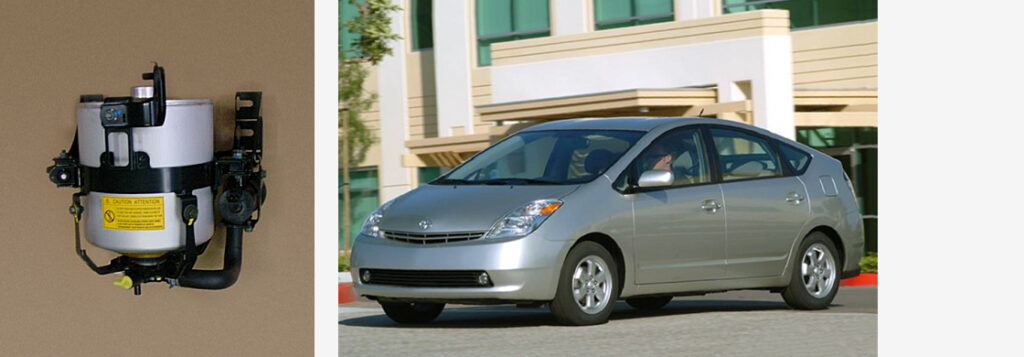

In the past, our vacuum-insulated hot water tanks have also been adopted for use in thermal energy storage systems for automobile engine coolant.

Seeking to remain a company loved by everyone for the next 100 years, we began exploring how we could use this technology to help solve current societal issues.

I also personally have experience in the planning and development of vacuum-insulated bottles, where I promoted environmental initiatives and plastic waste reduction. This led to my desire to create a new business that would provide solutions for Tiger’s next 100 years.

The Challenge of Processing 0.05mm “Foil”: A Tough Nut to Crack

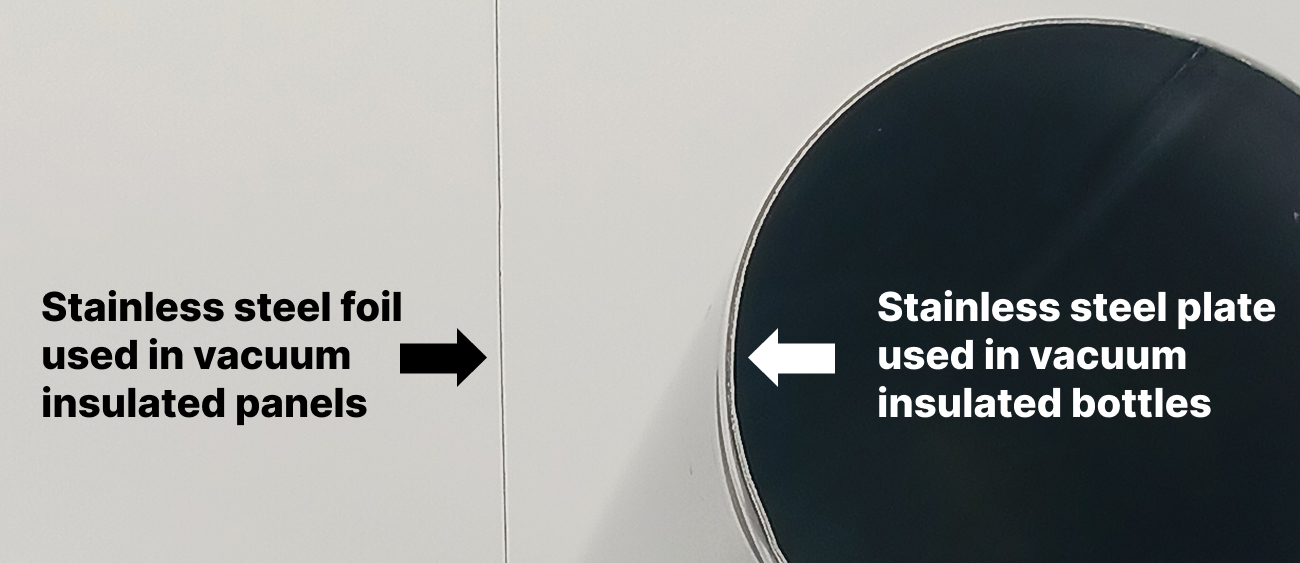

The fundamental concept for our current product was actually formulated a decade ago in 2015. At that time, we were exploring new technology development themes, wondering if we could combine our existing technologies to create something new. The focus landed on vacuum insulation material. While other companies had vacuum insulation materials made from non-stainless materials, they had issues with durability and fire resistance.

Creating a vacuum insulation material from stainless steel would enable a much longer lifespan than previously possible. While this concept is simple in theory and something anyone could come up with, the difficulty in processing the material is incomparably higher than producing stainless steel bottles.

A Turning Point in 2022, After an Antarctic Field Test

In 2020, we conducted a test of our vacuum insulated panels for residential use to see if they could provide efficient insulation in harsh environments like Antarctica. However, our manufacturing process at the time relied heavily on manual labor, which made mass production a challenge. This issue became clear, and we weren’t able to move forward with the development.

“If we could commercialize this, it would pave the way for Tiger’s next 100 years…”

I felt frustrated, but our existing stainless steel bottle processing equipment just couldn’t handle the extremely thin stainless steel needed for the panels. It would punch a hole in it instantly. Plus, getting new equipment would be too expensive…

Just as I was thinking about all of this, in 2022, Osaka Prefecture announced a public call for businesses to participate in its “Carbon Neutral Technology Development and Demonstration Project,” which supports companies developing and testing cutting-edge technologies that contribute to carbon neutrality. We entered the competition and were fortunate to be selected.

This allowed us to re-evaluate our welding techniques and change our manufacturing methods, giving us a fresh start.

To be more specific, we developed a unique welding technique to improve speed and stability.

This new method eliminated the need for specialized craftsmanship, ensuring that anyone could achieve the same high quality of welding.

This breakthrough finally put mass production within our reach.

However, even after the project was selected, we were plagued by problems. Every time we made a prototype, a hole would form, making it impossible to maintain the vacuum. We created and failed with hundreds of prototypes before finally achieving a breakthrough.

Why was Tiger Corporation able to take on the challenge of developing “vacuum insulation panels”?

The passion at the heart of it

Why was Tiger Corporation able to develop thin, high-performance vacuum insulation panels, something other companies haven’t?

I believe it’s because of two key factors: the vacuum insulation technology it has cultivated over more than a century, and its prior experience working in space development. This included a project commissioned by JAXA to develop a “”double-walled vacuum insulated container”” for transporting valuable experiment samples from the International Space Station.

Even back then, when we were developing the “double-walled vacuum insulated container” for the JAXA project, our in-house development team had the mindset to overcome high hurdles with technology. They believed in taking on challenges that other manufacturers might consider too difficult. This corporate culture—which finds meaning in contributing to society through innovative work—was one of the key factors that enabled us to fully commit to the development. Our long history of applying vacuum insulation technology beyond everyday products, including our work on vehicle equipment development for over 20 years and our involvement in space development for more than a decade, is now being leveraged to its full potential.

The future Tiger Corporation envisions through “vacuum insulation panels.”

After we introduced our vacuum insulation panels, we received some great feedback from companies in the logistics and housing industries.

We heard things like, “”We have a history of constantly exploring products using vacuum insulation panels, but we were never able to make them a reality. It’s incredible that you did—we have high hopes!”” Another major point of positive feedback was, “The long lifespan is a huge benefit. We want to try using it.”

In the future, we believe the range of applications will expand to include residential properties, renovations, warehouses, data centers, and container houses. Going forward, we will continue to contribute to the realization of a sustainable society through technological innovation.

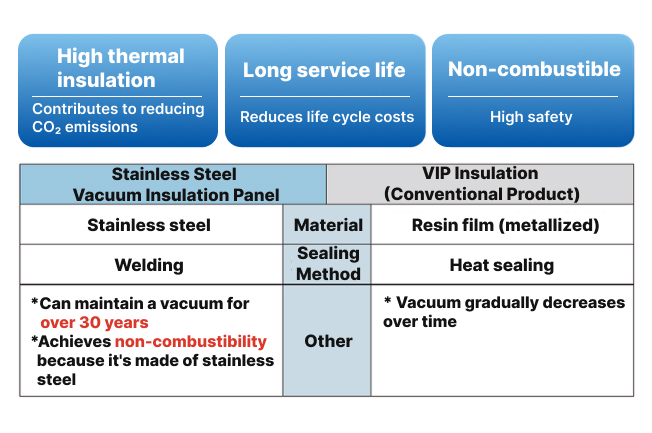

Three Features of the Stainless Steel Vacuum Insulation Panel

1.High Thermal Insulation

Because the interior is in a vacuum, it achieves an excellent thermal conductivity of 0.0025 W/m·K or less (*1), which is approximately 10 to 25 times higher than conventional insulation materials.

2.Long service life

By using stainless steel, we have achieved long-term vacuum insulation maintenance for over 30 years (*2).

3.Non-flammability

The use of stainless steel ensures safety due to the panel’s non-flammable properties

*1 Initial measured values based on JIS A 1412-2 for a prototype 10 mm thick and 440 mm square or larger in size (calculated by our measurement method)

*2 Estimated value based on actual gas permeability of the materials used (calculated by Tiger’s in-house measurement method)

Exhibition at the EXPO 2025 Osaka, Kansai, Japan

・Date & Time: October 7 (Tuesday) to October 13 (Monday), 2025

・Location: Inside the EXPO 2025 Osaka, Kansai, Japan venue (West Gate side), at the Future Life Village, Future Life Experience

・Exhibition Content: Tiger Corporation’s Stainless Steel Sealed, Long-lifespan,

Non-flammable Vacuum Insulation Panel Technology Development and Demonstration”

Related Links

About Vacuum Insulation Technology>

What is “Vacuum Insulation Technology,” a core competence of Tiger Corporation

Stainless Steel Vacuum Insulation Panel TIVIP>

Learn about the mechanism and features of Tiger’s Stainless Steel Vacuum Insulation Panel. With its high thermal insulation, long lifespan, and non-flammability, it is expected to play a major role in the transportation and building materials industries

[[Reference Information | Tiger Corporation]]

The history of Tiger Corporation, as its name suggests, began with the manufacturing of thermoses.

Since creating our first glass thermos for the Japanese domestic market, branded with the “Tiger” mark, in 1923, we have delivered what was once a luxury item to households as an everyday necessity, through a relentless accumulation of creative innovation and sincere craftsmanship.

Ever since, we have provided comfort and convenience for various aspects of daily life by creating products that utilize two key technologies: “vacuum insulation technology,” as seen in our vacuum insulated bottles and thermal pots, and “heat control technology,” used in our rice

cookers, beginning with the electric rice warmer that originated in 1970.

By applying our core technologies of “vacuum insulation technology” and “heat control technology,” we continue to take on challenges beyond consumer products. We are active in a wide range of cutting-edge industries that are shaping the future, including space missions, medical transport for specimens and reagents that require strict temperature control, engine coolant heat storage systems for hybrid vehicles, and the development of next-generation building materials for highly insulated homes.

Catalog

About Industrial Equipment Solutions

Contact Us

For more information, contact us from here;

On research and development, methods of applying vacuum insulation technology,

and inquiries about partnership