Vacuum Insulated Bottle MMZ-K035/K050/K060

PRODUCT CONCEPT

Simple and basic bottle – that is easy to use anytime, anywhere

MMZ-K035

MMZ-K050

MMZ-K060

1. Spinning Process

The stainless-steel plate is pressed and thinned with Tiger’s original manufacturing process to make the bottles lightweight.

2. Antibacterial processed plastic lid parts

We adopted the antibacterial process in the plastic lid parts certificated by SIAA, in order to offer hygienic bottles to daily life. Products that meet the following three criteria are authorized to indicate SIAA marks, “Antimicrobial property”, “Safety”,and “Appropriate Labeling”.

About antibacterial processed

MMZ-K uses silver-antibacterial processed polypropylene resin (the parts listed below at the subject area).

Testing method:The material meets JIS Z 2801,test for antimicrobial activity and efficacy

Subject area:Inner stopper, gasket *See manual for details

Processing method:

Inner stopper – Kneading into plastic

Gasket – Kneading into silicone rubber

Ingredient material:Ag inorganic antibacterial agent

Testing result:Antibacterial activity value 2.0 and more

Antibacteria means “inhibiting the proliferation of bacteria.”

3. Plastic lid parts have been authorized by the SIAA (Society of International sustaining growth for Antimicrobial Articles)

– Subject area: Inner stopper

SIAA registration number: JP0122676X0001G

Antibacterial processed plastic lid parts

We adopted the antibacterial process in the plastic lid parts certificated by SIAA, in order to offer hygienic bottles to daily life. Products that meet the following three criteria are authorized to indicate SIAA marks: (1) Antimicrobial property (*1), (2) Safety (*2), (3) Appropriate Labeling (*3).

(*1) Antimicrobial property

The proportion of bacteria on the surface of the product is 1/100 or less of that on the surface of a non-treated product, and the antimicrobial effect remains after durability tests. Antimicrobial properties are determined from the results of tests conducted in accordance with the ISO 22196 international standard.

(*2) Safety

The criteria for safety established by SIAA have been met.

(*3) Appropriate Labeling

On exhibit are the types and treated parts of antimicrobial agents.

4. Smooth rimmed mouth

Tiger’s meticulously designed mouth makes the drinking experience natural and comfortable.

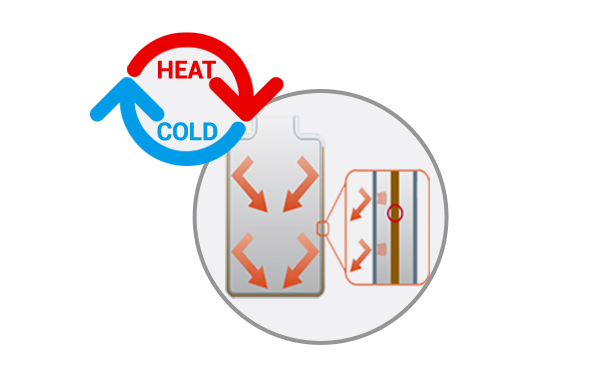

5.Vacuum Insulation Technology

Tiger’s vacuum insulation technology keeps drinks hotter and colder for hours. The copper foil in between the two stainless-steel walls supports temperature retention. Cold drinks will not cause condensation on the outside of the bottle and hot drinks will not cause the bottle to become too hot to handle.

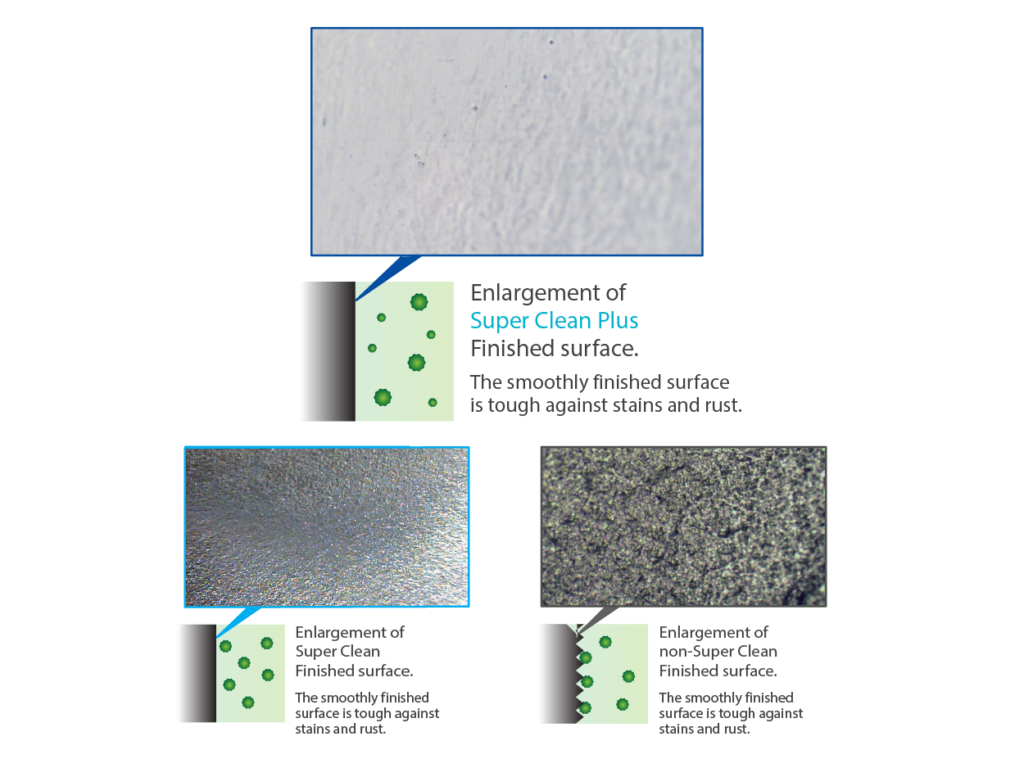

6. Super Clean Plus

The inside of Tiger’s bottles has smooth and polished surface that is tough against stains and rust.

7. Leaser welding

Leaser welding, Tiger’s original technique, used in the bottom part prevents water from entering in between the two stainless-steel walls. It makes the body washable entirely and well drained.

8. High-grade stainless steel

Tiger’s vacuum insulated bottles are made from SUS304 (18/8) high-grade certified food-safe stainless steel.

| Product number | MMZ-K035 | MMZ-K050 | MMZ-K060 |

|---|---|---|---|

| Color |

Steel Black<KS> Frost White<WF> Misty Pink<PM> Matte Stainless<XM> |

Steel Black<KS> Misty Pink<PM> Frost White<WF> Matte Stainless<XM> |

Matte Stainless<XM> Steel Black<KS> |

| Capacity | 0.35L | 0.5L | 0.6L |

| Heat Retention (6h) | 69℃ or more | 74℃ or more | 76℃ or more |

| Heat Retention (1h) | 86℃ or more | 88℃ or more | 89℃ or more |

| Cold Retention (6h) | 8℃ or less | 7℃ or less | 7℃ or less |

| Size W×D×H (Approximate value) | 6.6×6.6×16.4(cm) | 6.6×6.6×21.6(cm) | 6.6×6.6×25.1(cm) |

| Weight (Approximate value) | 0.17kg | 0.19kg | 0.23kg |

| Caliber (Approximate value) | 4.4(cm) | 4.4(cm) | 4.4(cm) |

| Producing Country | China | China | China |