Play the movie

Maker of everyday stainless steel containers develops

space-age insulation technology

Space has become the next frontier in science, providing an environment for groundbreaking experiments that cannot be conducted on Earth. But for the results to benefit us, they need to be transported back to Earth in perfectly sealed containers. Enter Tiger, a company that until now has mostly been known for their stainless steel thermal bottles and other utensils.

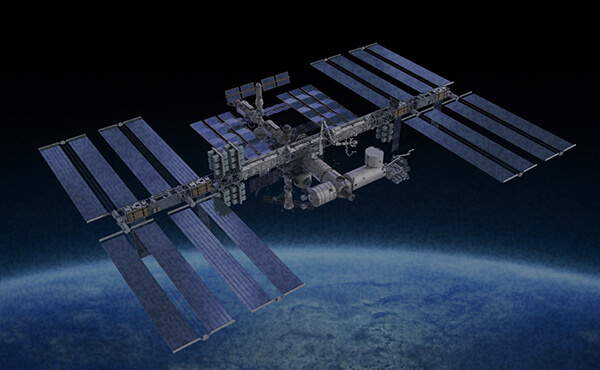

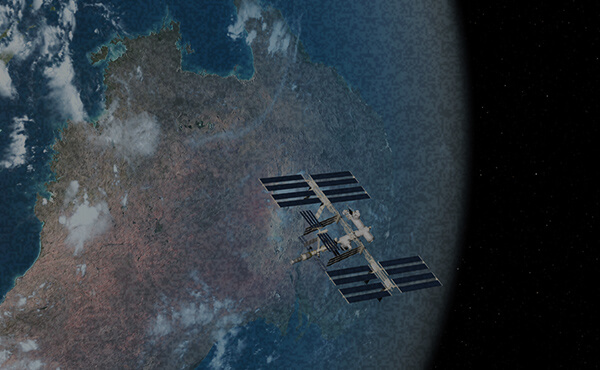

In September 2018, Japan launched the Kounotori 7 into outer space on a mission to supply the International Space Station (ISS). The Japan Aerospace Exploration Agency (JAXA) decided to use this occasion to validate a method for transporting experimental samples from the ISS safely back to Earth, which it did in November the same year.

Japan had never attempted such a feat before, but they succeeded in part thanks to the double-walled, vacuum-insulated container incorporated in the small re-entry capsule developed by JAXA that was carried on board the Kounotori 7. This container was developed by the Tiger Corporation.

Using the knowledge and top-tier insulation technologies the company had built over the course of a century, Tiger helped JAXA ensure that these precious samples survived the harsh temperatures of outer space—and the enormous 40G impact when the capsule landed in the ocean upon returning to Earth.

-

Kennedy Space Center

-

Rendezvous

-

The ISS

-

Departure from the ISS

-

Johnson Space Center

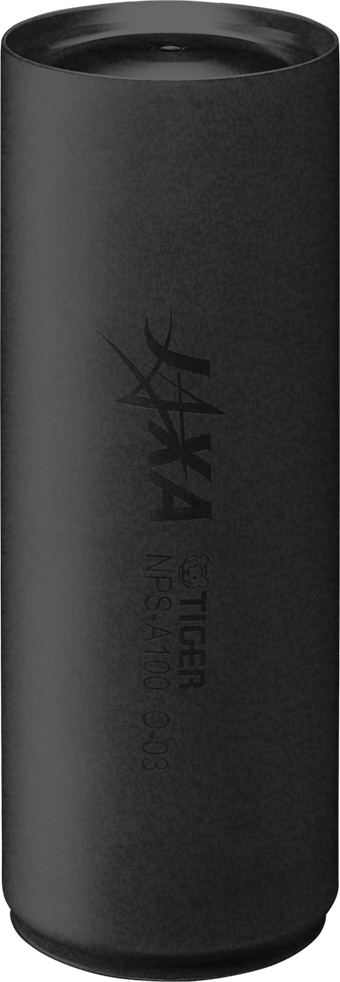

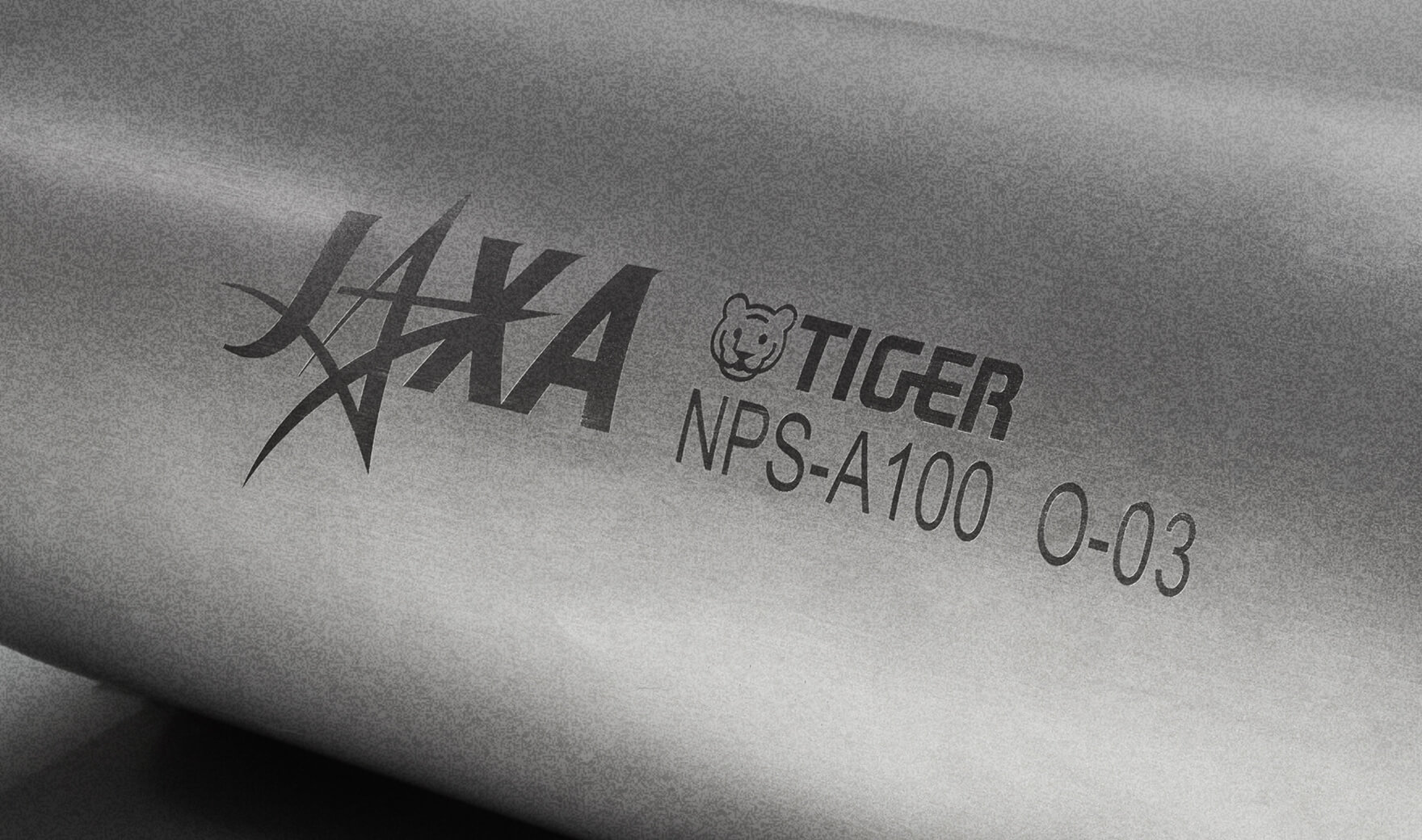

This summer, Tiger will enter Phase Two of its outer space challenge. Working with JAXA and Technosolver, a space solutions consultant, they have developed a new double-walled, vacuum-insulated container for carrying experimental samples back to Earth from outer space missions led by JAXA—and this container will be placed on board the SpaceX CRS-22 spacecraft in its upcoming voyage.

The mission is as follows:

To transport the results of the protein crystal growth experiment being conducted inside the Kibo Laboratory Module of the ISS, safely bringing the crystallized protein back to Earth.

Developing a container that could fulfill this mission was not easy, as Tiger needed to meet three strict requirements.

CONSIDERABLE

MASS REDUCTION

Create a compact container weighing no more than 4.7 kg (10.3 lb) including the ice pack while still offering high-quality vacuum insulation.

RIGID TEMPERATURE

CONTROL

Maintain the temperature inside the container at 20℃ ± 2℃ (68°F ± 3.6°F)—with the aid of only ice packs—to preserve samples for at least twelve days, from the time the container is loaded onto the spacecraft before its launch to when the container is retrieved at the ISS. This requirement also covers the at least 7.5 days it takes for samples to be transported from the ISS to Earth.

LONG-TERM

DURABILITY

Make the container more durable so it lasts at least three years or six missions.

Demonstrating the ability of Tiger’s double-walled, vacuum-insulated container to preserve experimental samples even in a more lightweight and downsized form will be crucial for greatly expanding the application of JAXA’s experiments in outer space. The samples that will be protected inside Tiger’s container on this mission are valuable—they will help advance the field of medicine and lead to new cures that will benefit all of humanity.

Stay tuned to keep updated on this all-important mission.

It’s no exaggeration to say that the history of the Tiger Corporation is the history of insulation technology itself. Since our founding in 1923, we have maintained an unwavering focus on improving insulation for a wide range of usages. Instead of being satisfied with the tried and tested, we’ve pursued one innovation after another with the restless spirit of the pioneer. As a result, we have become leaders in our field.

Perhaps no story better illustrates our constant push to go further than our involvement in the Kounotori 7 space mission that the Japan Aerospace Exploration Agency (JAXA) launched in 2018. Part of the mission involved placing experimental samples from the International Space Station (ISS) inside a small re-entry capsule developed by JAXA and Technosolver, a space solutions consultant, to be released for recovery in the Pacific Ocean on the way back to Earth. JAXA tapped Tiger to develop a double-walled, vacuum-insulated container to incorporate in the capsule.

Since there were no means to insulate the capsule via electricity, we built on our 100 years of experience manufacturing and refining stainless steel thermal bottles to develop a purpose-built double-walled, vacuum-insulated container from scratch. The samples were placed inside this container, along with ice packs to ensure the temperature inside remained at the required low levels throughout the capsule’s voyage to Earth. As a result, the samples were recovered on Earth intact.

It was a historic moment for Japan, which until then had not developed their own means for recovering materials from the ISS.

The road leading up to that moment was paved with challenges. We needed to meet two Herculean conditions—maintaining the temperature of the samples inside the container at 4℃ ± 2℃ (39.2°F ± 3.6°F) over the course of four or more days and ensuring the container could resist the enormous 40G impact when the capsule landed in the ocean upon returning to Earth. For the engineers at Tiger, working on a product designed for outer space was like opening up a completely new frontier, and it took a lot of trial and error to perfect the design.

Thanks to the success of JAXA’s mission, Tiger’s name has been etched in history. We have now entered a new chapter where our vacuum insulation technology will play an increasingly important role in space travel and exploration.

We’ve also set our horizons beyond space. Transportation solutions for medical samples and reagents that require storage under strict temperature conditions; hybrid car systems for storing heated coolant so it can be used to warm the engine when necessary; next-gen building materials that can provide a high level of insulation even in severe environments—such as the South Pole—with no drop in quality: the potential applications of our vacuum insulation technology are limitless. This technology will support cutting-edge fields in every industry, helping them lead us towards a dynamic, exciting future.